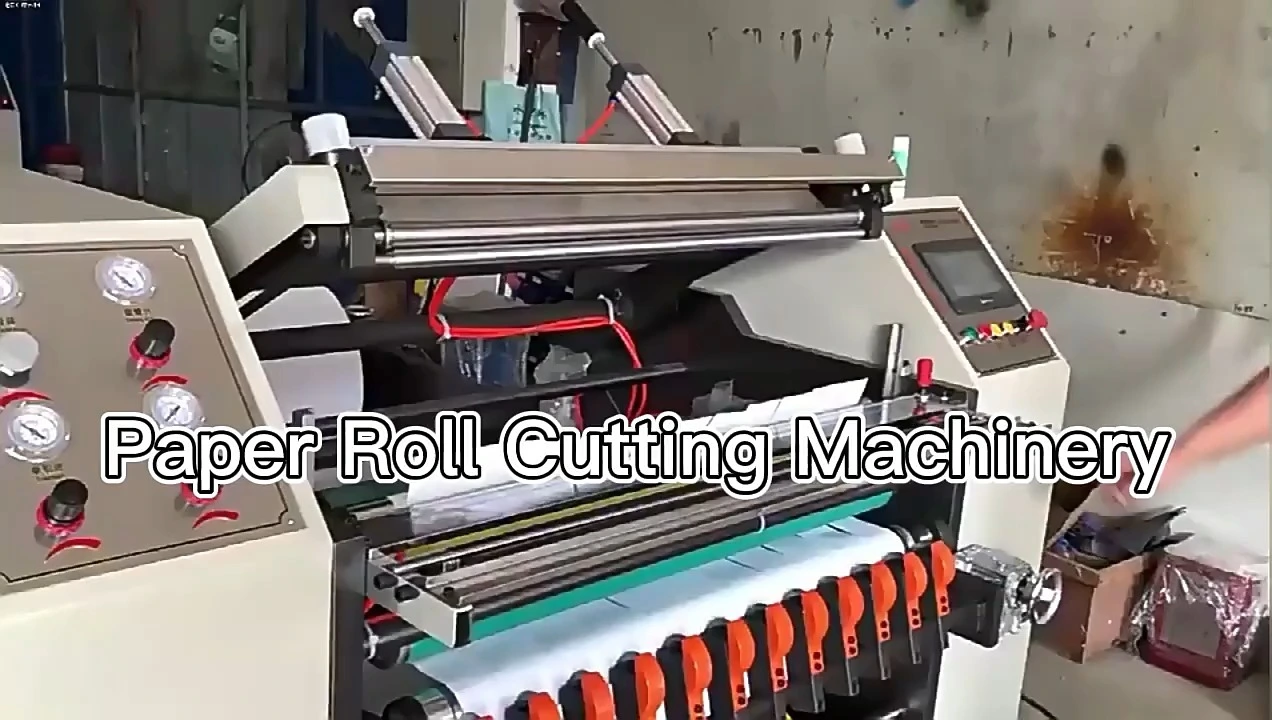

Jentera Pemotong Gulungan Kertas Terma Automatik Berkelajuan Tinggi Mesin Pemotong Kertas Terma Gulungan dan Penggulungan Semula

Model: ZM-GW-FQ-900

MOQ: 1

Masa penghantaran: 30-60 hari

Mulakan Pelabuhan: Guangzhou, Ningbo, Shenzhen dll,.

Persijilan: CE, IOS, RUSH dll,.

Jenama: Putera

Harga Kilang: berunding

Keupayaan bekalan: 1000 Set/Set setiap Bulan

Terma pembayaran: L/C, Tunai, T/T, Western Union, Jaminan Perdagangan, Paypal

ODM & OEM: Ada

Skop bekalan:

Satu enjin utama

Lepaskan aci udara 1 pc

Pemotong atas 5 keping (dalam kotak alat)

Pemotong bawah 5 keping (dalam kotak alat)

Putar semula aci ø12 mm, ø 15 mm, ø 17 mm 2 keping setiap satu

Satu set alat perata

Pengawal boleh atur cara MIKOM 1 pc

Satu penyongsang MIKOM

Satu skrin sentuh MIKOM

Pengawal ketegangan WENNEW 1pc

Məhsul parametrləri

Məhsulun adı | OR-1000VA |

Max.Cutting Size | 340*300mm |

Min.Cutting Size | 80*80mm |

Max.Cutting Height | 60mm |

Min.Cutting Book Height | 10mm |

Min.Single Cutting Height | 5mm |

Cutting Speed | 1100 times/H |

Güc | 4KW |

Overall Dimension | L1520*W1820* H1680mm |

Machine Weight | 1700kq |

Model | ZM-GW-FQ-900 |

Maks. Jumbo Roll Width | 860mm |

Maks. Jumbo Roll Dia. | 1000mm |

Maks. Rewinding Dia. | 150mm |

Maks. Unwinding Speed | 150m/min |

Unwinding Shaft | 3” Pneumatic Air Expanding Shaft |

Çəki | 1000kq |

Gərginlik | 3 Phase 380V 50HZ |

Rewinding Shaft in Diameter | 0.5'',1 inch ,Coreless(8mm) |

Overall Dimensions | 2050*1600*1500mm |

Məhsul təsviri

Thermal paper slitting machine is mainly applied for slitting thermal paper, fax paper, cash register paper, carbon-less paper,and other kinds of paper grammage that less than 250gsm. It equips PLC +touch screen control, automatic tension control, automatic product separation, automatic counting, automatic pneumatic loading system, which make it easy to operate by only one worker. Its features are high speed and stability, high precision, and long working life. The defective rate is only 3‰.It brings much more profit to clients than before. It is the most ideal slitting machine for small size paper roll producing.

Məhsul Xüsusiyyətləri

more Təfərrüatlar

Product Show

Applicable

A thermal paper slitter, also known as a thermal paper rewinder or a thermal paper cutting machine, is specifically designed for the precise and efficient cutting of thermal paper into smaller rolls. Here are some typical use cases and applications for a thermal paper slitter:

1. Retail and Point of Sale (POS) Systems:

•Application: Producing rolls of thermal paper for cash register receipts, credit card slips, and POS terminals.

•Benefits: Ensures consistent quality and size for smooth operation in POS printers.

2. Automated Teller Machines (ATMs):

•Application: Cutting thermal paper for ATM transaction receipts.

•Benefits: Reliable and precise cutting to match the specific requirements of ATM printers.

3. Medical and Healthcare Settings:

•Application: Creating rolls of thermal paper for medical record keeping, patient charts, and diagnostic equipment like ECG machines.

•Benefits: High-quality printing for clear and legible records.

4. Faxes and Communication Devices:

•Application: Producing thermal fax paper rolls.

•Benefits: Efficient production of fax paper rolls that meet the size and quality standards for clear transmission.

5. Printing and Office Supplies:

•Application: Manufacturing rolls of thermal paper for office printers, including label printers and ticket printers.

•Benefits: Customizable roll sizes and lengths to fit various printer models.

6. Logistics and Shipping:

•Application: Producing rolls of thermal paper for shipping labels, waybills, and tracking documents.

•Benefits: Precise cutting and consistent quality for accurate and durable labels.

7. Gaming and Entertainment:

•Application: Cutting rolls of thermal paper for lottery tickets, gaming machines, and amusement park receipts.

•Benefits: Fast and efficient production to meet high-volume demands.

8. Manufacturing and Production Lines:

•Application: Cutting thermal paper for production line tracking, inventory management, and quality control documentation.

•Benefits: Streamlined production processes and improved traceability.

9. Service Industries:

•Application: Producing thermal paper for restaurant orders, hotel bills, and airline boarding passes.

•Benefits: Quick and easy production of high-quality prints for customer-facing documents.

10. Custom Applications:

•Application: Customizing thermal paper rolls for specific industries or niche applications.

•Benefits: Tailored solutions that meet unique requirements, such as specialized coatings or unusual sizes.