Streamlining Production With An Automatic Hot Foil Stamping Machine

Are you looking to improve the efficiency and quality of your production process? Look no further! In this article, we will explore the benefits of using an automatic hot foil stamping machine to streamline your production. From enhancing productivity to achieving consistent results, this innovative technology is revolutionizing the manufacturing industry. Join us as we delve into the advantages of integrating this advanced machine into your production line.

Introduction to Hot Foil Stamping

Hot foil stamping is a printing technique that adds a touch of luxury and professionalism to a wide range of products, from stationery and packaging to promotional materials and labels. The process involves applying a metallic or colored foil to a surface using heat and pressure, creating a glossy and eye-catching finish. In recent years, the demand for hot foil stamping has increased, and many businesses are turning to automatic hot foil stamping machines to streamline their production processes.

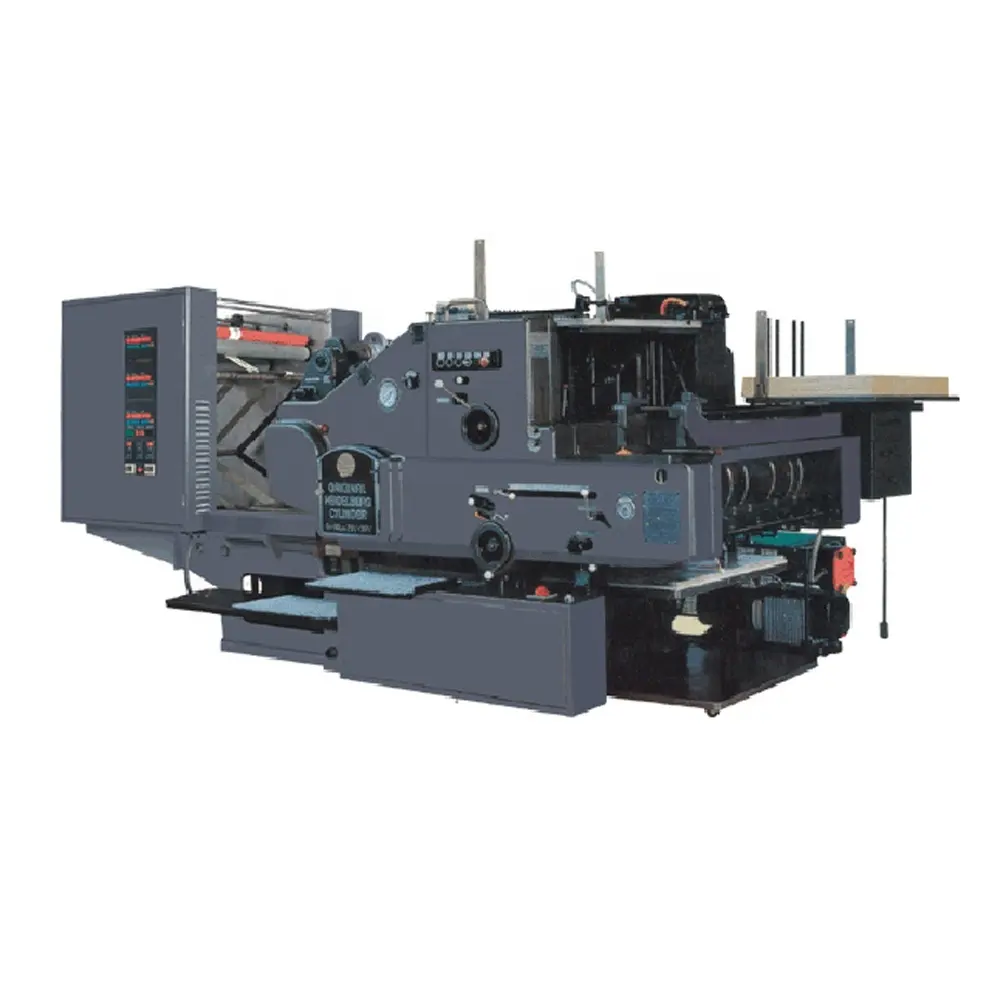

An automatic hot foil stamping machine is a versatile and efficient piece of equipment that can significantly improve the efficiency and quality of hot foil stamping operations. These machines are designed to handle large volumes of work with minimal human intervention, making them ideal for high-volume production environments. In this article, we will provide an in-depth introduction to hot foil stamping and explore the benefits of using an automatic hot foil stamping machine in a production setting.

Hot foil stamping involves transferring a thin layer of foil onto a surface using a heated die and pressure. The process begins with the design being etched onto the surface of the die, which is then heated and pressed against the foil and the substrate material. The heat and pressure cause the foil to adhere to the substrate, creating a durable and visually striking finish. This technique is widely used in the printing and packaging industry to add a premium look and feel to products, helping them stand out in a competitive market.

An automatic hot foil stamping machine automates the hot foil stamping process, allowing for faster and more consistent results. These machines are equipped with advanced features such as programmable controls, automatic foil feeding, and adjustable pressure settings, enabling them to handle complex designs and large production runs with ease. Additionally, automatic hot foil stamping machines are designed for quick setup and changeovers, reducing downtime and increasing overall productivity.

One of the key benefits of using an automatic hot foil stamping machine is the elimination of manual labor, which reduces the risk of errors and inconsistencies in the finished product. By automating the stamping process, businesses can achieve higher levels of precision and efficiency, resulting in cost savings and improved product quality. Furthermore, automatic hot foil stamping machines allow for greater flexibility in design and customization, as they can accommodate a wide range of foil colors and substrates.

In conclusion, hot foil stamping is a versatile and impactful printing technique that can enhance the visual appeal and perceived value of a wide range of products. By investing in an automatic hot foil stamping machine, businesses can streamline their production processes and achieve consistent and high-quality results. Whether it's adding a touch of elegance to packaging or creating premium promotional materials, automatic hot foil stamping machines are a valuable asset for any business looking to elevate their brand and stand out in a competitive market.

The Benefits of Using an Automatic Hot Foil Stamping Machine

In the world of manufacturing and printing, efficiency and quality are key factors to success. One of the emerging technologies that has been revolutionizing the industry is the automatic hot foil stamping machine. This cutting-edge piece of equipment offers a wide range of benefits for businesses, from streamlining production processes to enhancing the overall quality of the final product. In this article, we will explore the numerous advantages of using an automatic hot foil stamping machine and how it can significantly impact the success of a business.

First and foremost, an automatic hot foil stamping machine offers unparalleled efficiency in the production process. Traditional foil stamping methods often require manual labor and are time-consuming. However, with an automatic hot foil stamping machine, the process becomes much faster and more streamlined. The machine is capable of handling large volumes of work with minimal human intervention, allowing businesses to increase their production output significantly. This efficiency not only saves time but also reduces labor costs, making it a cost-effective solution for businesses of all sizes.

Moreover, the use of an automatic hot foil stamping machine also leads to a drastic improvement in the overall quality of the final product. The machine is designed to apply foil with precision and consistency, resulting in a flawless finish every time. This level of accuracy simply cannot be achieved through manual stamping methods, making the automatic hot foil stamping machine a game-changer for businesses looking to elevate the quality of their products. Whether it is for packaging, promotional materials, or other printed products, the machine ensures a professional and high-end appearance that is sure to impress customers.

Additionally, the machine offers a wide range of customization options, allowing businesses to create unique and eye-catching designs that stand out in the market. From various foil colors to intricate patterns and textures, the automatic hot foil stamping machine provides businesses with the flexibility to meet the diverse needs of their customers. This level of customization can help businesses differentiate themselves from competitors and enhance brand recognition, ultimately leading to increased sales and customer loyalty.

Furthermore, the use of an automatic hot foil stamping machine also contributes to sustainability efforts. Unlike traditional methods that often produce excess waste, the machine generates minimal scrap and uses minimal energy, making it an environmentally friendly option for businesses. This not only aligns with the growing demand for sustainable and eco-friendly products but also reflects positively on the reputation of the business.

In conclusion, the benefits of using an automatic hot foil stamping machine are undeniable. From streamlining production processes to enhancing product quality and offering customization options, the machine has the potential to significantly impact the success of a business. As the industry continues to demand efficiency, quality, and sustainability, the automatic hot foil stamping machine emerges as a valuable investment for businesses looking to stay ahead of the competition.

How to Implement an Automatic Hot Foil Stamping Machine in Production

In today’s fast-paced manufacturing environment, finding ways to streamline production processes is essential for staying competitive. One way to achieve this is by implementing an automatic hot foil stamping machine in your production line. This article will guide you through the process of integrating this advanced technology into your operations.

An automatic hot foil stamping machine is a versatile and efficient tool that can be used to add decorative and functional finishes to a wide range of products. It uses a combination of heat, pressure, and metallic or pigmented foil to create a visually striking impression on a variety of materials, including paper, cardboard, plastics, and leather. This process is commonly used in the production of packaging, labels, promotional materials, and luxury goods, among others.

The first step in implementing an automatic hot foil stamping machine in your production line is to assess your current processes and identify areas where this technology could make a meaningful impact. Consider the types of products you manufacture, the volume of production, and the specific finishing requirements of your customers. By understanding these factors, you can determine how an automatic hot foil stamping machine can improve the quality, efficiency, and overall capabilities of your operations.

Once you have identified the potential benefits of integrating this technology into your production line, the next step is to evaluate the different models and features available in the market. Automatic hot foil stamping machines come in a variety of sizes and configurations, each with its own set of capabilities and specifications. Some machines are designed for high-speed, high-volume production, while others are more suitable for smaller batches and custom jobs. Consider factors such as the size of your production facility, the skill level of your operators, and the specific requirements of your customers when selecting the right machine for your needs.

After selecting the most suitable automatic hot foil stamping machine for your production line, the next step is to install and integrate it into your operations. This process involves preparing the necessary infrastructure, such as electrical connections, ventilation, and workspace layout, to ensure the machine operates safely and efficiently. Additionally, training your staff on how to operate and maintain the machine is essential for maximizing its performance and longevity.

Once the automatic hot foil stamping machine is fully integrated into your production line, you will start to see significant improvements in the quality, speed, and versatility of your finishing processes. The machine’s automated features, such as programmable settings, precise temperature control, and quick changeover capabilities, will enable you to efficiently handle a wide range of finishing tasks with minimal downtime. Additionally, the consistent and precise results achieved with hot foil stamping will help enhance the overall appeal and marketability of your products.

In conclusion, implementing an automatic hot foil stamping machine in your production line can greatly improve the efficiency and quality of your finishing processes. By carefully evaluating your needs, selecting the right machine, and integrating it into your operations, you can take a significant step towards streamlining your production and staying ahead of the competition in today’s dynamic manufacturing landscape.

Streamlining the Production Line with Automatic Hot Foil Stamping

In today’s fast-paced industrial environment, efficiency is key. Businesses are constantly seeking ways to streamline their production processes in order to meet increasing demand and stay ahead of the competition. One such solution that has revolutionized the production line is the automatic hot foil stamping machine.

The automatic hot foil stamping machine is a powerful tool that has transformed the way products are manufactured. It works by using heat and pressure to apply a thin layer of metallic or pigmented foil onto a surface, creating a luxurious and eye-catching finish. This process is not only fast and efficient, but also highly versatile, making it suitable for a wide range of materials including paper, cardboard, plastic, and even leather.

One of the key advantages of using an automatic hot foil stamping machine is its ability to streamline the production line. With traditional stamping methods, the process of applying foil to a product was often time-consuming and labor-intensive. However, with the introduction of automatic machines, this has changed dramatically. These machines are capable of running continuously, tirelessly applying foil to a high volume of products with minimal human intervention. This not only saves time and labor costs, but also ensures consistent and high-quality results.

Furthermore, the automatic hot foil stamping machine offers a level of precision and accuracy that is difficult to replicate with manual processes. Through advanced technology and precise control systems, these machines can ensure that the foil is applied with the exact amount of pressure and heat, producing flawless and uniform results every time. This level of consistency is essential for businesses looking to maintain a strong and reputable brand image, particularly in industries where aesthetics play a crucial role in product appeal.

Another important benefit of using an automatic hot foil stamping machine is its ability to handle a wide variety of designs and patterns. Whether it’s intricate logos, decorative patterns, or custom text, these machines can effortlessly transfer virtually any design onto a product surface with stunning clarity and detail. This level of versatility allows businesses to explore numerous creative options and add a unique and personalized touch to their products, ultimately increasing their market appeal.

Additionally, the automatic hot foil stamping machine is an environmentally friendly solution. Unlike traditional methods that often require the use of harsh chemicals and solvents, these machines operate with minimal waste and emissions, making them a sustainable and eco-friendly choice for businesses that value environmental responsibility.

In conclusion, the automatic hot foil stamping machine is a game-changer for businesses looking to streamline their production line. With its ability to rapidly and efficiently apply foil to a wide range of materials, its precision and accuracy, its versatility in design options, and its environmentally friendly operation, this machine has become an indispensable tool for businesses seeking to enhance their production processes and maintain a competitive edge in today’s market. As technology continues to advance, it’s clear that the automatic hot foil stamping machine will only become even more vital for businesses looking to meet the demands of a dynamic and evolving industry.

Future Trends in Automation for Hot Foil Stamping Technology

The demand for hot foil stamping technology continues to rise in various industries, from packaging and labeling to stationery and promotional materials. As the need for customization and personalization grows, the demand for efficient and reliable hot foil stamping machines is also on the rise. In response to this growing demand, manufacturers are continuously developing innovative solutions to streamline production and improve efficiency. One of the most significant advancements in this field is the integration of automation into hot foil stamping machines.

Automatic hot foil stamping machines are revolutionizing the industry by offering a range of benefits, from increased speed and precision to reduced labor costs and improved overall production quality. Future trends in automation for hot foil stamping technology are poised to further enhance these advantages, making it a key area of focus for manufacturers and industry professionals.

One of the most significant aspects of future trends in automation for hot foil stamping technology is the development of advanced software and control systems. These systems are designed to optimize production processes, minimize waste, and maximize the utilization of materials. In addition, they offer real-time monitoring and diagnostics, allowing operators to identify and address issues as they arise, minimizing downtime and improving overall efficiency.

Furthermore, the integration of robotic systems and high-speed handling equipment is a key trend in automation for hot foil stamping technology. Robotic systems can be programmed to handle a wide range of tasks, from loading and unloading materials to performing intricate and precise stamping operations. These systems not only increase the speed of production but also improve the consistency and quality of the stamped products.

Another future trend in automation for hot foil stamping technology is the development of smart sensors and intelligent control systems. These systems are designed to enhance the precision and accuracy of the stamping process, ensuring consistent and high-quality results. Additionally, they offer the capability to adapt to changing production requirements, allowing for greater flexibility and customization.

The implementation of Industry 4.0 principles is also shaping the future of automation for hot foil stamping technology. This involves the integration of smart, connected machinery and advanced data analytics to optimize production processes and facilitate predictive maintenance. By leveraging the power of data and connectivity, manufacturers can achieve higher levels of efficiency, productivity, and quality control.

In conclusion, the future of automation for hot foil stamping technology is promising, with advancements in software, robotics, intelligent control systems, and Industry 4.0 principles poised to revolutionize the industry. As manufacturers continue to push the boundaries of innovation, automatic hot foil stamping machines are set to become even more essential in streamlining production and meeting the growing demand for customized and high-quality stamped products.

Conclusion

In conclusion, the addition of an automatic hot foil stamping machine has revolutionized our production process, allowing us to streamline our operations and increase efficiency. With 20 years of experience in the industry, we understand the importance of staying ahead of the curve and investing in cutting-edge technology. The automatic hot foil stamping machine has enabled us to consistently deliver high-quality products to our customers in a more timely manner. As we continue to grow and evolve, we remain committed to embracing advancements in technology and staying at the forefront of innovation in the industry.