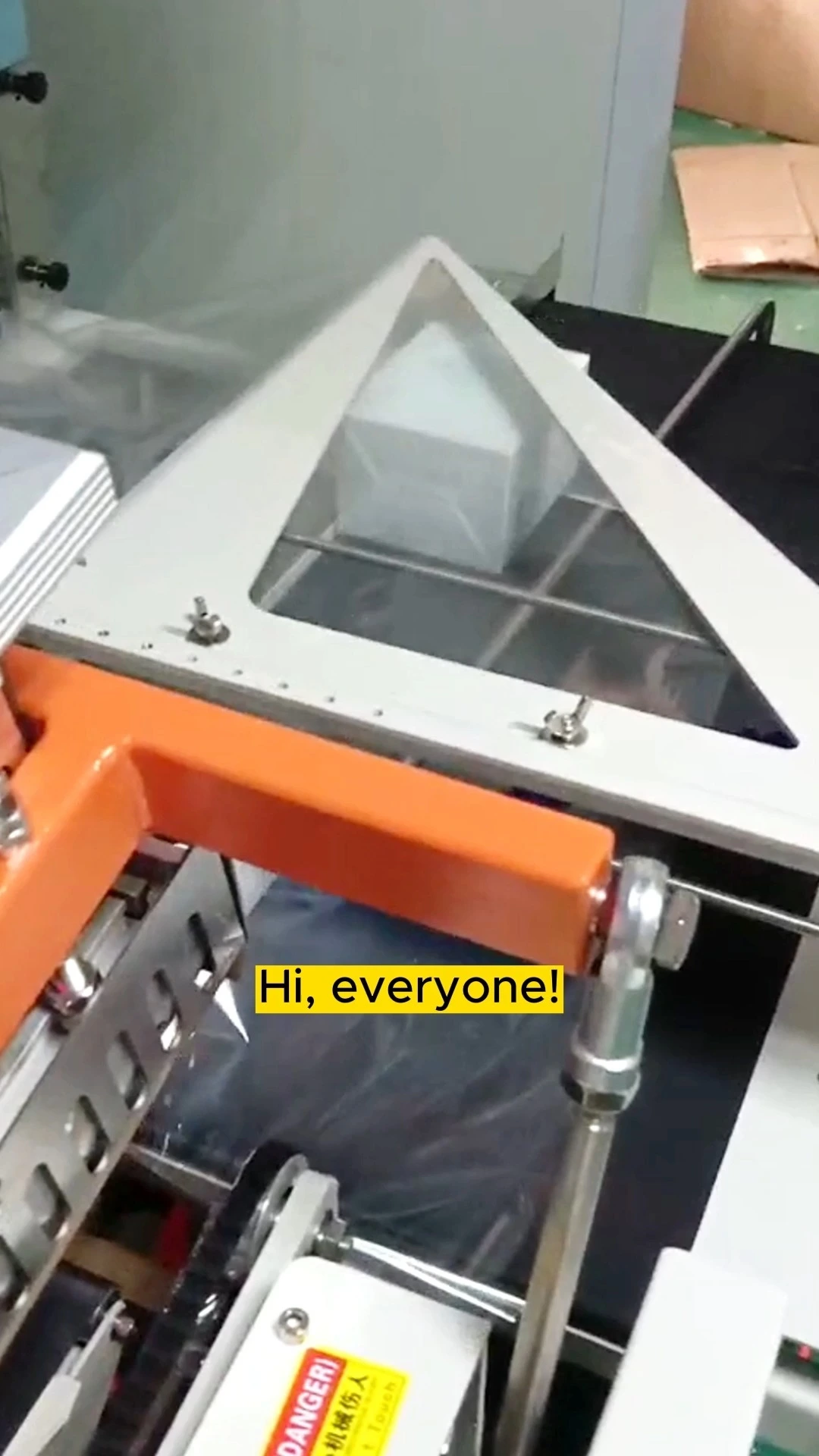

Automatic Boxes Cans Thermal Shrink Wrap Packing Machine Water Bottle PE Film Heat Shrink Tunnel Wrapping Packaging Machine

Model :FQL450A

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Model |

FQL450A |

|

Max. packaging size L+H(H<150mm) |

< 500mm |

|

Max. packaging size W+H(H<150mm) |

< 400mm |

|

Sealing knife size |

550*450 |

|

Machine dimension |

1650*800*1450mm |

|

Machine weight |

300kg |

|

Applicable shrink film |

POF.PE.PVC |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

Warranty of core components |

1 years |

|

Core Components |

Hard Cover Book Machine |

Place of Origin |

Henan, China |

|

Weight |

300 KG |

Warranty |

2 years |

|

Key Selling Points |

Automatic |

Condition |

New |

|

Automatic Grade |

Automatic |

Brand Name |

PRINCE |

|

Voltage |

380V |

Dimension(L*W*H) |

1700*830*1450mm/1600*560*660mm |

|

Key Selling Points |

Easy to Operate |

Model |

FQL450A |

|

Speed of packing |

15-30packets/min |

Seal size L*W(mm) |

570*470 |

|

Machinery Test Report |

Provided |

Power |

1.6kw |

Product Description

Automatic Heat shrink tunnel wrapping machine can be used for automatic online shrink packaging of products, the use of photoelectric automatic detection of products, can choose automatic feeding or manual feeding two modes, the use of folding film and other three sides can be sealed.

more feature

More Details

Production Process

1. Product Loading

Manual or Automatic Feeding:

The products are placed on a conveyor belt either manually or automatically, depending on the packaging line's setup. Products could be single items or bundles of multiple items (e.g., six-packs of bottled drinks).

Film Selection:

The packaging film, typically made of polyethylene (PE), polyolefin (POF), or polyvinyl chloride (PVC), is fed into the machine from a film roll. The choice of shrink film depends on the product, with different types offering various benefits like transparency, durability, or puncture resistance.

2. Film Wrapping

Film Enclosure:

As the product moves along the conveyor, the shrink film is wrapped around it. Some shrink machines use a continuous roll of film, while others may use pre-made shrink bags. The machine typically wraps the film either around individual products or over a group of items to create a multipack.

Sealing:

Once the product is wrapped, the excess film is sealed using a heat-sealing bar or L-bar sealer. The seal is usually made at one or more points to fully enclose the product. The sealed film now forms a loose pouch around the item(s).

3. Heat Shrinking

Heat Tunnel:

After sealing, the product with the loosely wrapped film is transported through a heat tunnel. The tunnel has heaters or blowers that circulate hot air around the film, causing it to shrink evenly around the product.

Temperature Control:

The temperature in the shrink tunnel is carefully regulated depending on the type of shrink film being used. For instance, PVC requires lower heat compared to polyolefin films. Too much heat can damage the product or film, while too little heat will not shrink the film effectively.

Film Contraction:

As the product moves through the tunnel, the heat causes the shrink film to contract tightly around it, conforming to the shape of the item or package. This step creates a snug, tamper-proof, and professional-looking package.

4. Cooling and Solidifying

Cooling Station:

Once the product exits the heat tunnel, it is passed through a cooling station, which uses ambient air or fans to quickly cool down the heated film. Cooling solidifies the tight fit around the product.

Final Inspection:

After cooling, the package is inspected for any defects such as uneven shrinking, tears in the film, or incomplete sealing. If all packaging criteria are met, the product is ready for labeling, boxing, or shipping.

Applicable

1. Food and Beverage Industry

Bundling and Protection:

In the food and beverage industry, shrink packaging is frequently used to bundle multiple units, such as bottles, cans, or jars. It provides a durable and transparent covering, making it easy to identify products while offering protection during transit.

Preservation and Hygiene:

Shrink packaging provides a barrier against dust, moisture, and contamination, making it ideal for fresh and processed foods. Products like meat, cheese, and bakery items are often shrink-wrapped to preserve freshness and prevent spoilage.

Tamper-Evidence:

Many food products are shrink-wrapped to provide tamper-evidence. The shrink film clearly shows if the product has been tampered with, ensuring the customer receives an untouched item.

2. Pharmaceutical and Medical Industry

Product Integrity:

In the pharmaceutical and medical industries, shrink packaging helps maintain the integrity of sensitive products like medications, medical devices, and surgical tools by protecting them from environmental exposure.

Tamper-Resistant Packaging:

Shrink wrapping provides tamper-resistant packaging, which is critical for ensuring the safety and authenticity of pharmaceutical products. Consumers can easily identify if a product has been compromised.

Multipackaging:

Shrink packaging is also used to bundle medication blister packs, vials, or boxes for easy distribution in bulk, which enhances storage efficiency and reduces packaging waste

3. Electronics and Consumer Goods

Dust and Moisture Protection:

Electronics and consumer goods, such as headphones, mobile accessories, and gadgets, are often shrink-wrapped to shield them from dust, moisture, and other contaminants. Shrink packaging preserves product quality and extends shelf life.

Unitizing and Branding:

Electronics manufacturers frequently use shrink wrapping to bundle items (e.g., cables with chargers or multiple components), offering a cost-effective and branded packaging solution that also reduces shipping costs..