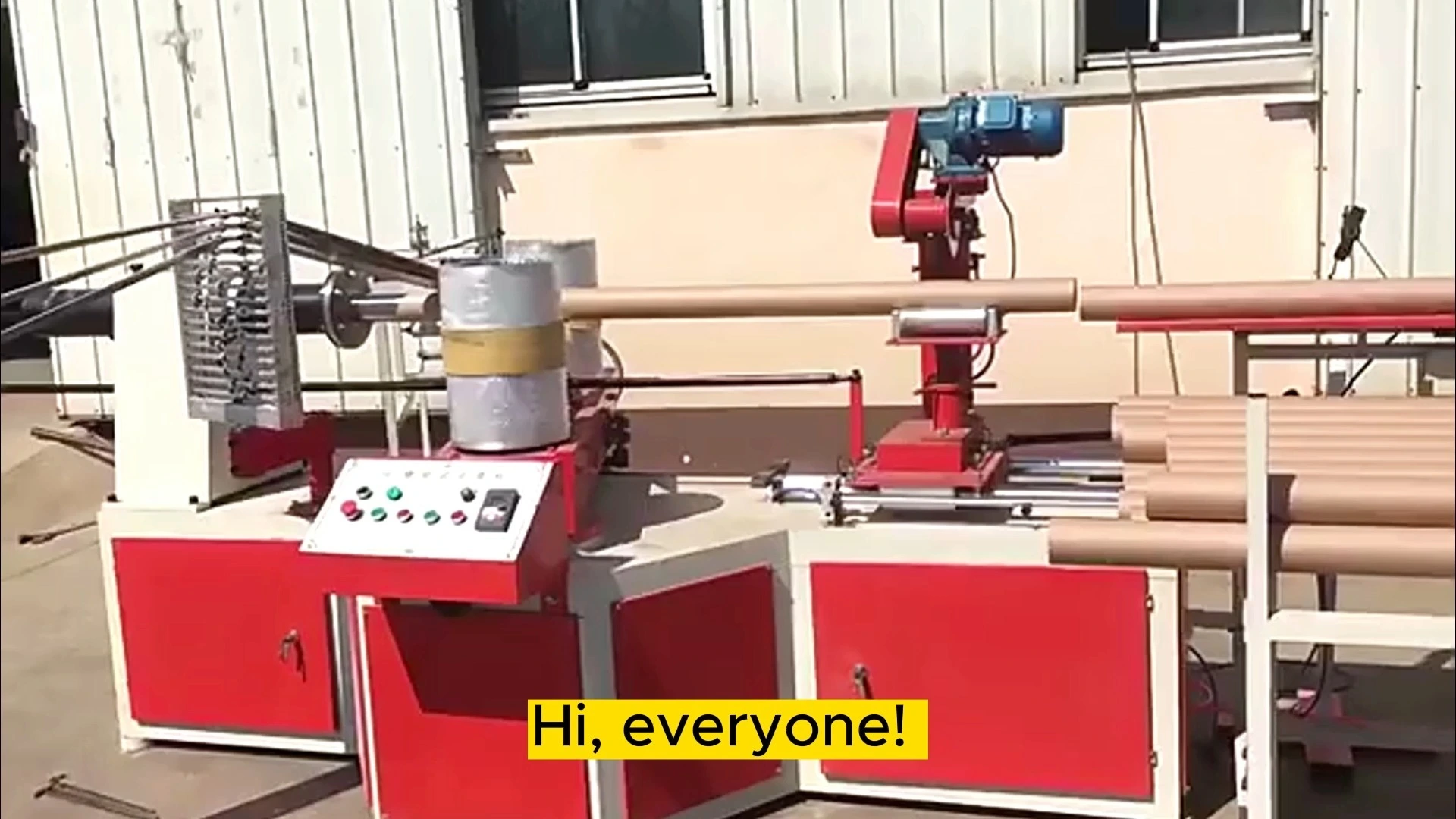

Firecrackers Cardboard Paper Tube Core Rolling Winding Cutter Machine Parallel Paper Tube Production Cutting Making Machine

Model :OR-2150B

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Model |

OR-2150B |

OR-2150SF |

OR-4250B |

OR-4250SF |

|

Paper layer |

3-16 layers |

3-16 layers |

3-21 layers |

3-21 layers |

|

Max. pipe diameter |

150mm |

120mm |

250mm |

250mm |

|

Min.pipe diameter |

20mm |

20mm |

40mm |

40mm |

|

Max.pipe thickness |

8mm |

8mm |

20mm |

20mm |

|

Min.pipe thickness |

1mm |

0.5mm |

1mm |

1mm |

|

Speed |

3-20m/min |

3-30m/min |

3-20m/min |

3-30m/min |

|

Power |

5.5KW |

7.5KW |

11KW |

15KW |

|

Voltage |

380V 50Hz |

380V 50Hz |

380V 50Hz |

380V 50Hz |

|

Main machine size |

2.8*1.8*1.95m |

4*2*1.95m |

4.2*2*1.95m |

4.2*2*1.95m |

|

Weight |

1500kg |

3200kg |

4200kg |

4200kg |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Product Type |

Paper Tube Machine |

Warranty of core components |

1 years |

|

Paper Core Thickness |

0.5-8mm |

Place of Origin |

Henan, China |

|

Weight |

2800 KG |

Warranty |

2 years |

|

Key Selling Points |

Automatic |

Condition |

New |

|

Automatic Grade |

Automatic |

Brand Name |

PRINCE |

|

Voltage |

380V |

Dimension(L*W*H) |

3.2*2*1.95m |

|

Paper Core width |

20mm-150mm |

Power |

4KW |

Product Description

Paper core machine is mainly used for the core of toilet paper rolls.We have different models of core machines to choose from, which can make paper tubes of different diameters and thicknesses.The finished paper tube can be cut and discharged automatically.It has infrared ray and automatic transmission to make the cutting length more accurate.

more feature

More Details

Product Show

Production Process

Paper Tube Production (Making) Process:

Paper Loading:

Rolls of kraft paper or other types of paper are fed into the machine. Multiple layers of paper can be loaded depending on the thickness and strength required for the tube.

Glue Application:

Adhesive (usually water-based glue) is applied uniformly to the paper layers as they enter the forming section to ensure proper bonding and rigidity.

Tube Forming:

The glued paper layers are wound around a rotating mandrel, forming a cylindrical shape. This is done using a spiral or parallel winding technique, depending on the type of tube being produced.

1. Spiral Winding: Paper is wound at an angle around the mandrel, creating a spiral seam.

2. Parallel Winding: Paper is wound in a straight, parallel manner.

Drying:

Some machines may have a built-in drying system to ensure the glue cures and the paper tube solidifies quickly. This step improves the tube's strength and ensures it holds its shape.

Tube Cutting (Length Cutting) Process:

Tube Positioning:

After the paper tube is formed, the machine positions the tube for cutting. The desired length is pre-set, either manually or through an automated control system.

Cutting:

Circular blades or rotary cutters move across the paper tube and cut it into the specified length. The machine typically cuts multiple tubes in succession, with an automatic feeding system pushing the tube forward for each cut.

Finished Product Collection:

The cut paper tubes are collected either manually or automatically into bins or onto conveyors for further processing, packaging, or shipment.

Repeat Process:

The cycle is repeated, and the machine continues to produce and cut paper tubes until the batch is completed.

Applicable

Applications of a Paper Tube Production Cutting Making Machine:

Packaging Industry:

1.Paper tubes are used as cores for winding various materials like plastic films, stretch films, paper rolls, fabrics, and foils.

2.In addition, they are used as protective sleeves for shipping fragile products or as spacers in packaging.

Textile Industry:

Paper tubes are used to wind yarns, threads, and textiles. They provide the core for spools and cones in textile production.

Printing and Paper Industry:

Paper tubes are essential for paper rolls in printing presses, plotters, receipt printers, and large-format printers.

Adhesive Tape and Label Industry:

They serve as cores for adhesive tapes, labels, and stickers, ensuring smooth unwinding during application.

Construction Industry:

Paper tubes are used for creating molds for casting concrete columns, as well as for creating void forms in construction.

Automotive and Industrial Applications:

Paper tubes can be used in the production of bushings, gaskets, and spacers for various automotive and industrial applications.

Food Industry:

Paper tubes are used as packaging for products such as chips, snack foods, or other cylindrical-shaped goods.

Craft and Stationery:

In the stationery industry, paper tubes are used to manufacture pencil holders, art materials, and product displays.

Pharmaceutical and Medical Applications:

Paper tubes are used for packaging medical products like gauze rolls or as cores for sterile medical films and bandages..