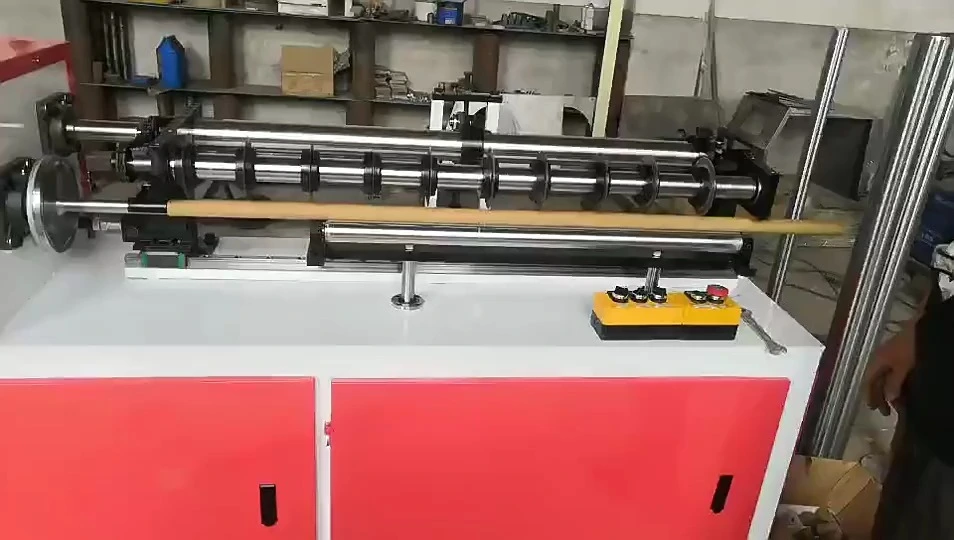

Multiple Blades Cardboard Paper Tube Core Cutter Slitter Cutting Slitting Machine Automatic Small Parallel Paper Tube Cutting Machine

Model :SKD-1.5-1300

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Model |

SKD-1.5-1300 |

|

Paper tube length |

1300mm |

|

Paper thickness |

1-5mm |

|

The number of cutter |

10 |

|

Speed of mainshaft |

525r/min |

|

Voltage |

380v |

|

Power |

1.5kw |

|

Air pressure |

3MPa |

|

Weight |

360kg |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

Warranty of core components |

1years |

|

Product Type |

Paper Tube Machine |

Place of Origin |

Henan, China |

|

Weight |

460 KG |

Warranty |

1 years |

|

Model |

SKD-1.5-1300 |

Condition |

New |

|

Paper tube length |

1300mm |

Brand Name |

PRINCE |

|

Voltage |

380V |

Dimension(L*W*H) |

2285*770*1330mm |

|

Paper thickness |

1-5mm |

Power |

1.5KW |

Product Description

This multiple blades paper tube cutting machine is a multi-knife cutting machine for cutting paper tubes, the length of the paper tube is 1300mm, the diameter of the paper tube is customized by the customer. The paper tube slitting machine uses pneumatic cutting, and only one operator is required to complete the cutting work.

more feature

More Details

Product Show

Production Process

Workflow of a Small Parallel Paper Tube Cutting Machine:

This machine is designed to cut paper tubes of various diameters and lengths precisely. The typical workflow includes the following steps

Loading the Paper Tube: The operator manually or automatically loads the paper tube onto the machine's mandrel or chuck.

Setting the Length: The desired length of the cut sections is entered into the machine's control panel or set manually.

Tube Positioning: The paper tube is positioned for the first cut. Many machines use automated feeding mechanisms to push the tube forward incrementally for multiple cuts.

Cutting: The cutting unit, which usually contains circular or rotary blades, is activated. The blades move across the tube, cutting it precisely into sections of the desired length.

Unloading: After cutting, the sections are either manually removed or automatically ejected from the machine.

Repeat Process: The cycle is repeated for subsequent tubes, ensuring consistent and accurate cuts.

Applicable

Applications of a Small Parallel Paper Tube Cutting Machine

Packaging Industry: Paper tubes cut into precise lengths are used in the production of cores for wrapping materials like plastic films, paper rolls, textiles, and adhesive tapes.

Textile Industry: Small paper tubes are commonly used as yarn and thread cores for spools.

Printing and Paper Industry: These tubes serve as the core for paper rolls in printers, plotters, and large-format printers.

Construction Industry: Small cut paper tubes can be used for concrete casting molds in construction or as spacers for structural elements.

Label and Tape Manufacturing: Paper tubes cut into specific lengths are used as cores for adhesive tapes and labels, both in industrial and retail applications.

Stationery Products: Used in making small tubes for products like pencil holders, calendars, or even disposable paper pens.

.