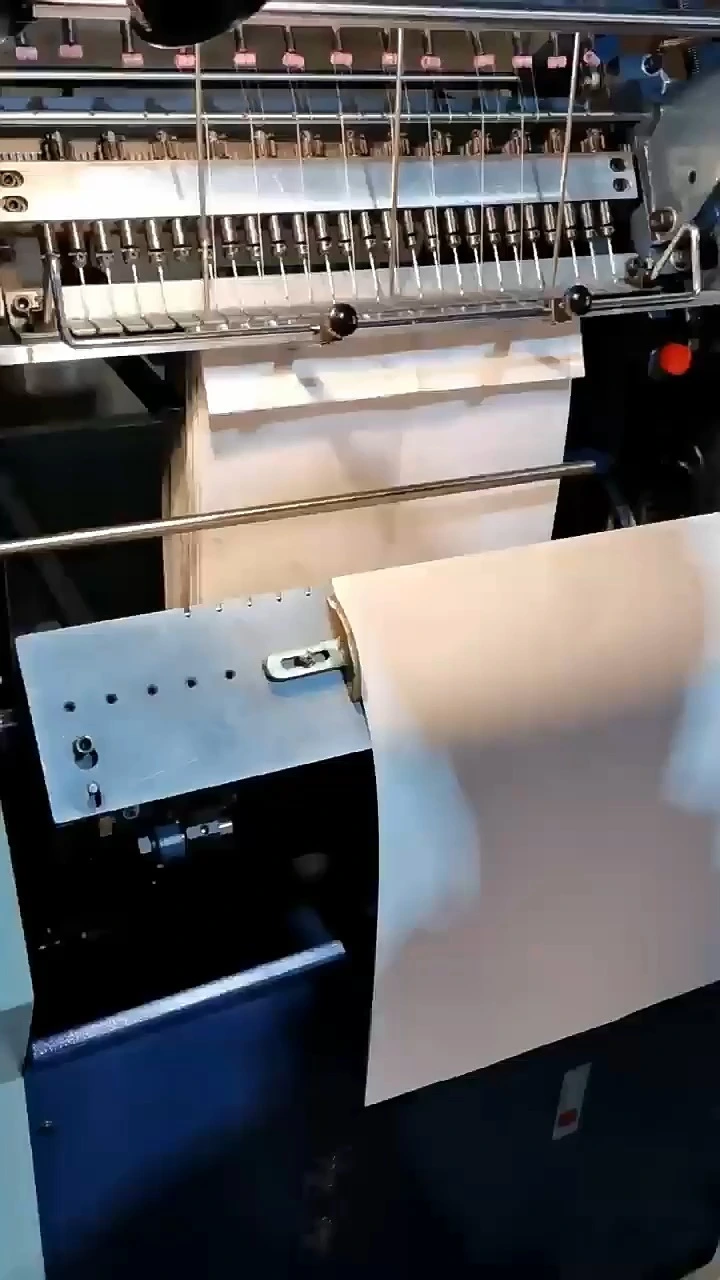

High-Speed Automated Elliptic Perfect Binding Machine with Automatic Cover Feeding

Notebook Book Cover Feeding, 1800-2000 Books/Hour

High-Efficiency Production: Utilizes a four-clamp elliptic circulation system for continuous operation, achieving speeds of up to 1800 books/hour, significantly boosting binding efficiency.

Perfect Binding Quality: The dual bottom gluing + dual glue control function ensures flat and sturdy book spines, while the milling and grooving process enhances glue penetration, delivering professional-grade binding results.

Intelligent Temperature Control: The PID precision temperature control system maintains hot melt glue at its optimal state, adapting to various materials and environmental conditions.

Automated Operation: The PLC program control + photoelectric recognition system automates the entire process—milling, gluing, cover application, and pressing—reducing manual operation complexity.

Safety & Eco-Friendly: Built-in paper scrap suction and exhaust systems keep the working environment clean, meeting modern printing facilities' environmental standards.

5.0

Start Port:

Ningbo,Qingdao,Shanghai,Shenzhen,Tianjin

Model NO.:

ST-50/3D

Minimum order quantity:

1

Price:

Negotiate

Certification:

CE

Payment Terms:

L/C,T/T,Western Union,Paypal

Delivery Time:

30-60 days

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product Name

Elliptic book glue binding machine

Machine Dimension

400X160X180 cm

Model NO.

ST-50/3D

Weight

2600

Product Description

Our Automatic elliptic book glue binding machine streamlines book production with precision hot melt glue binding, handling up to 1800 books/hour with flawless consistency for professional publishers and print shops.

Product Workflow

Here's a streamlined workflow of our notebook binder machine for professional, high-quality book production:

1.Manual Textblock Loading

Operators place the textblock (book interior) securely into the machine—simple and intuitive.

2. Milling

The spine is finely milled to create a rough surface, ensuring optimal glue penetration and a strong, lasting bind.

3. Glue Application

The ellipse system evenly applies hot melt adhesive along the spine with consistent temperature control, eliminating weak spots.

4. Automatic Cover Feeding

The machine automatically places and aligns the cover onto the glued textblock—saving time and improving accuracy.

5. Pressing & Forming

The book is firmly pressed to bond cover and pages, then shaped into a clean, square spine for a polished, professional finish.

6. Cooling & Output

After a brief cooling period, the bound book is ejected—ready for trimming or immediate use.

Perfect for: Print shops, copy centers, publishing houses, and organizations that demand reliable, attractive document binding.

Product Details

Milling & Grooving Unit

Features heavy-duty milling motor (3KW) that creates ideal surface for glue penetration, significantly enhancing binding strength and durability.

Pressure & Curing Station

Adjustable pressure mechanism with dwell time control ensures perfect adhesion between cover and book block without deformation.

Elliptic Book Clamp System

Four precision-engineered clamps rotate smoothly on elliptic track, ensuring stable book movement and perfect alignment during each binding phase.

Related Product

We offer a wide range of hot melt binding equipment tailored to your specific requirements—whether it’s based on usage scenario, frequency, binding thickness, warm-up time, binding speed, or adhesive type.

Product parameters

Product Specification

Other attributes

Key attributes

Industry-specific attributes

| type | Binding Machine |

| voltage | 380V |

| production capacity | 1800-2000 books/h |

| Working Width | 450*300mm |

| plc brand | other |

Other attributes

| warranty | 1 Year |

| Weight (KG) | 2550 |

| computerized | Yes |

| place of origin | China |

| brand name | Prince |

| dimension(l*w*h) | 3950x1600x1640 mm |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| Max. Book size | 160*120 mm-450*300mm |

| Binding Thickness | 3 ~ 60 mm |

| Binding Speed | 1800/2000 book/hour |

| Total Power | 17/18 kw |

| Clamp Quantity | 4/5(clamps) |

| Function | Book Glue Binding |

| Application | books perfect binding machine |

Packaging and delivery

| Selling units | Single item |

| Single package size | 400X160X180 cm |

| Single gross weight | 2600.000 kg |

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Looking For Automatic Printing and Packing Machines, Paper Processing, Paper Product Making, Machines? Partner With The Best.

no data

Related Products

no data

Useful Links

Products

Contact Us

Add:

4th Floor, Building 1, Baihui Industrial Park, Xiachang Village, Feiyun Street, Rui'an City, Wenzhou City, Zhejiang Province

Contact person: Cindy Xu

Tel: +86-19138012972

WhatsApp:+8619138012972

no data