Gold Supplier Water Bottle Production Line Full Automatic Plastic Water Bottle Filling Machine

Model :P-F-83

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:PRINCE

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Product Model |

ORF83 |

|

Production Capacity |

3000BPH /500ml |

|

Washing Head |

8 |

|

Filling Head |

8 |

|

Capping Head |

3 |

|

Suitable PET Bottle Size |

Diameter Φ70-Φ90, H:190-290mm,V: 330-1500ml |

|

Suitable cap Type |

Plastic Screw Cap |

|

Working Pressure |

0.25~0.3MPa |

|

Bottle Washing Flow |

0.5T/H |

|

Total Installed Power |

2.5KW |

|

Power Supply |

AC 3-380V/50HZ |

|

Overall Dimensions(mm) |

2000 x 1500 x 2200 |

|

Approx. Weight(kg) |

2000 |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Keyword |

Bottle Water Machine Production Line |

Warranty of core components |

1 years |

|

Core Components |

Hard Cover Book Machine |

Place of Origin |

Henan, China |

|

Weight |

2000 KG |

Advantage |

High Efficiency |

|

Key Selling Points |

Automatic |

Packing |

Wodden Case |

|

Automatic Grade |

Automatic |

Brand Name |

PRINCE |

|

Voltage |

220 |

Dimension(L*W*H) |

1640*1550*1680mm |

|

Feature |

Easy Operation |

After-Sales Service Provided |

Online Support |

|

Suitable For |

Water Filling Line |

Function |

Water Filling Machine |

|

Speed |

300bph/500ml |

Transport Package |

Wooden Case |

|

Specification |

2000*1500*2200mm |

Feed Cylinder Structure |

Multi-Room Feeding |

|

Dosing Device |

Rotor |

Structure |

Rotary |

Product Description

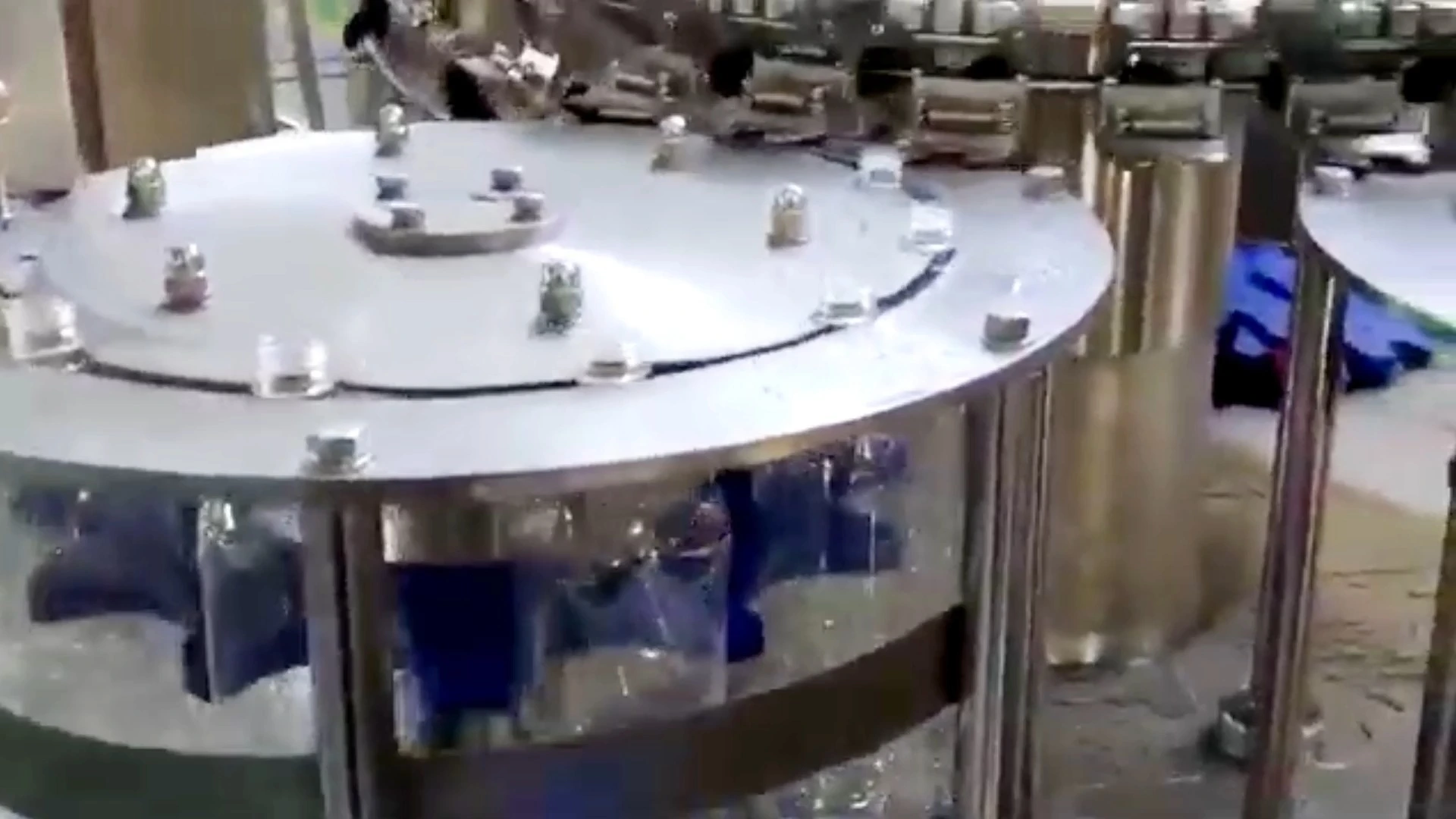

The OR-F-83 Wash-Filling-Capping 3-in-1 unit is a highly efficient piece of Beverage Machinery designed for the seamless production of bottled beverages. It not only streamlines the processes of washing, filling, and capping but also significantly reduces human contact with the product, thereby enhancing hygiene standards. This advanced machinery is ideal for producing a variety of beverages, including mineral water, purified water, and non-carbonated drinks, ensuring consistent quality while boosting production capacity and overall economic efficiency.

more feature

More Details

Production Process

Bottle Feeding:

Manual or Automatic: Bottles are either manually placed on the conveyor belt or automatically fed into the machine from a hopper or bottle unscrambler. The conveyor belt moves the bottles into the filling station.

Bottle Positioning:

Sensors and Stoppers: The machine uses sensors to detect the presence of the bottles. Bottles are precisely positioned and held in place by a pneumatic stopper or mechanical system to ensure proper alignment under the filling nozzles.

Filling Process:

Nozzle Insertion: The nozzles lower into the bottles, depending on the type of machine, to reduce splashing or foam creation. Some nozzles fill from the bottom up to prevent foam in carbonated or frothy liquids.

Filling Mechanism: Liquid is dispensed into the bottles using one of several filling mechanisms:

Gravity Filling: Relies on gravity for low-viscosity liquids (like water or juices).

Pump Filling: Uses mechanical pumps (peristaltic or piston) for accurate dosing, used for medium to high-viscosity liquids.

Vacuum Filling: Pulls the liquid into the bottles by creating a vacuum, suitable for thick liquids like oils.

Overflow Filling: Ensures that all bottles are filled to the same level by allowing excess liquid to overflow and be recirculated.

Bottle Sealing/Capping:

Once the liquid is filled, the bottles move to the capping station. Capping machines can be integrated for screw caps, corks, or press-fit caps, depending on the product.

Capping Mechanism: The caps are sorted and placed onto the bottles, then tightened or sealed

Applicable

Beverages: Used for filling drinks like water, juices, carbonated soft drinks, milk, alcoholic beverages (wine, beer, spirits), and energy drinks.

Oils: Filling edible oils such as olive oil, vegetable oil, coconut oil, and other cooking oils.

Sauces & Condiments: Used for ketchup, mustard, mayonnaise, sauces, jams, syrups, and dressings.

Dairy Products: Milk, yogurt, flavored milk, and liquid dairy products are often filled using these machines.

Liquid Food: Products like soups, gravies, and ready-to-eat liquid meals.