Rigid Paper Box Making Forming Machine

|

Model

|

DG-500

|

|

Rigid box length

|

45-500mm

|

|

Rigid box width

|

45 -400mm

|

|

Rigid box height

|

12-120mm

|

|

Speed

|

10-25pcs/min

|

|

Power

|

AC220V/50Hz/2.5kw

|

|

Weight

|

900KG

|

|

Dimensions

|

L1200mmxW1100mmxH2500mm

|

Product parameters

product description

The semi automatic gift box forming machine is an essential molding equipment for the production of Tiandi lid gift boxes, rigid boxes, and luxury packaging boxes. Designed for high-precision, fully automated manufacturing, this machine integrates folding, defoaming, shaping, and final molding into a single seamless process — delivering perfectly formed boxes with clean edges and consistent quality.

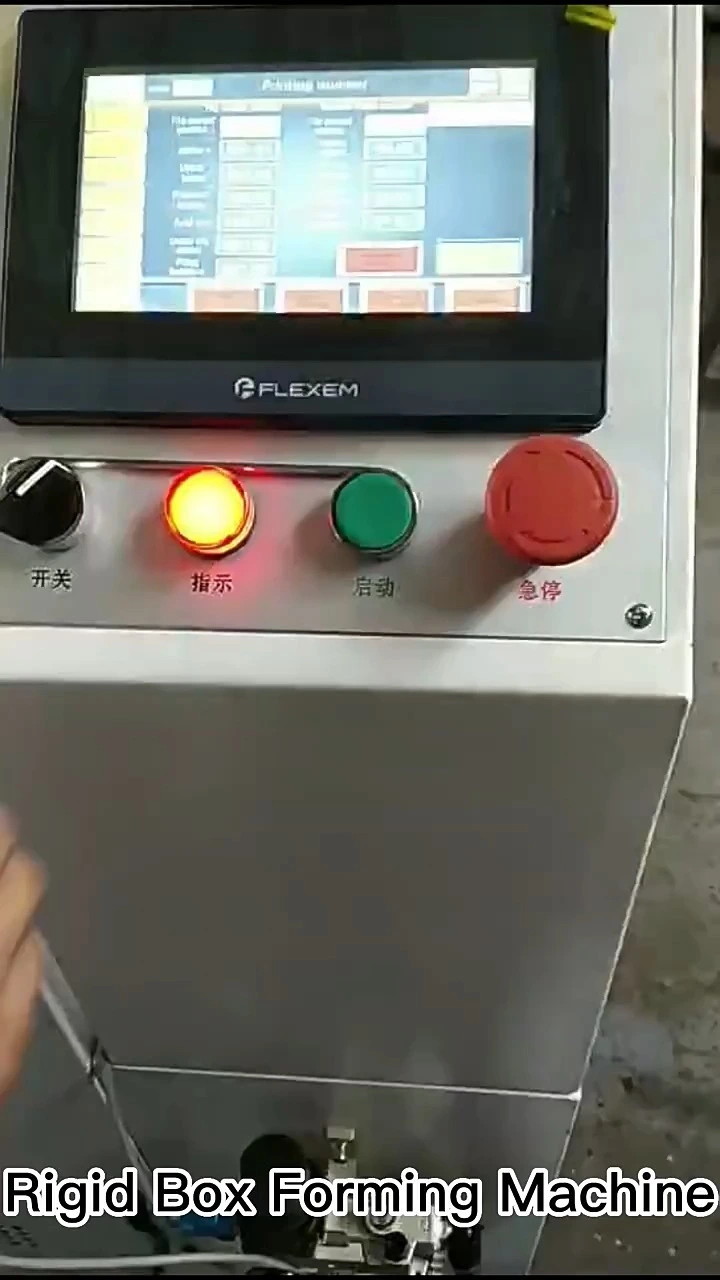

Equipped with a user-friendly touch screen interface and PLC programmable control system, the machine allows operators to easily set and save production parameters for different box sizes and styles. Whether you're producing small batches or running large-scale operations, the intuitive control panel ensures quick setup, stable performance, and minimal operator training.

This rigid box forming machine significantly improves production efficiency compared to manual methods — reducing labor costs and eliminating human error.

Product Details

Product molds Display

Real Shot: Our Trusted Rigid Box Molding for Premium Packaging

Designed with precision machining, the wooden mold accurately replicates the target rigid box’s structure—including the top and bottom box bodies, edge angles, and folding lines—guaranteeing consistent shaping results: neat, smooth edges, and a tight, perfect fit between the top and bottom boxes.

When paired with compatible rigid box-making equipment, this rigid box molding streamlines your production workflow: reduces manual adjustment time, minimizes defect rates, and ensures efficient delivery of premium, high-quality rigid boxes.

Product Display

Finish Product Display

Rigid Box Forming Machine Finished Products

From everyday storage paper boxes and perfectly sized mobile phone boxes, to heartfelt gift boxes and secure jewelry boxes , this machine excels at producing neatly structured rigid boxes and beyond.

Every finished box boasts smooth, burr-free edges and a tight fit between the lid and base, eliminating the need for secondary trimming.

Equipped with stable processing capabilities, this rigid box forming machine enables batch production of custom packaging—it seamlessly handles both small-batch custom orders (e.g., limited-edition gift boxes) and large-scale bulk production (for mass-market paper boxes or mobile phone packaging).

It is highly suitable for enterprises that use it for custom hard box production, electronic packaging solutions or high-end gift box manufacturing.

Related Product

Our customer service team is a dedicated, hard-working group specially selected for their enthusiasm and commitment to providing excellent customer service. They offer advice, answer any queries, and offer continuous support even after a purchase is completed.