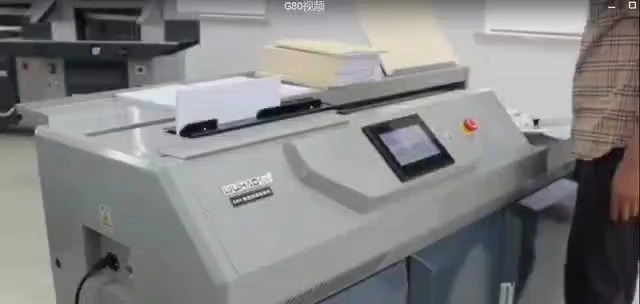

Factory selling Intelligent Frequency Conversion Hot Glue Book Binding Machine OR-G80

Model :ZM-OR-G80

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Model |

OR-G80 |

|

The max length of binding book |

430mm(A3) |

|

The max thickiness of binding book |

2pages-60mm |

|

Binding speed |

400 books/hour |

|

Slippage type |

beeline |

|

Glue melt time |

about 40 minutes |

|

Milling |

24 teeth sun knfie+milling knife |

|

Auto checking book thickness |

Yes |

|

Electric |

220V 50HZ 2100W |

|

Weight |

347kg |

|

Dimension |

1620*640*1020mm |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

Warranty of core components |

2 years |

|

Core Components |

Hard Cover Book Machine |

Place of Origin |

Henan, China |

|

Weight |

347 KG |

Warranty |

2 years |

|

Key Selling Points |

Automatic |

Condition |

New |

|

Automatic Grade |

Automatic |

Brand Name |

Prince |

|

Voltage |

220 |

Dimension(L*W*H) |

1620*640*1020mm |

|

Product name |

Book Binding Machine |

Function |

Book Binding Machine |

|

The Max Length of Binding Book |

430mm(A3) |

The Max Thickness of Binding Book |

2pages-60mm |

|

Binding Speed |

400Books/Hour |

Slippage Type |

Beeline |

|

Glue Melt Time |

About 40 Minutes |

Milling |

24 Teeth Sun knife+Milling Knife |

|

Power Supply |

220V 50HZ 2100w |

Production Capacity |

100pieces/Year |

Product Description

The OR-G80 Intelligent Frequency Conversion Hot Glue Book Binding Binder Machine offers versatile functionality, perfect for binding a diverse range of publications from books and albums to scratchpads and hardcover tomes. Its advanced technology is tailored to suit the demanding needs of graphic production centers, libraries, studios, SME printing firms, design & research institutes, publishing hubs, government bodies, and large corporations, ensuring seamless file binding for organized documentation and streamlined workflows.

more feature

Production Process

1. Stack the Pages: Neatly stack the pages that need to be bound. Use a jogger or manually align the pages so that they are flush on all sides.

2.Clamp the Pages: Depending on the machine, you may need to manually clamp the pages or place them in a built-in clamp. This will hold them in place during the binding process.

3.Cut the Cover: Ensure that the cover is cut to the correct size, slightly larger than the page size to allow for trimming.

4.Pre-Fold the Cover: Pre-fold the cover at the spine to ensure a clean, crisp fold once bound.

5. Position the Pages: Insert the aligned pages into the machine's binding slot. Ensure they are positioned correctly for the glue application.

6.Start the Machine: Activate the machine to begin the binding process.This often involves pressing a button or pulling a lever.

7.Glue Application: The machine will apply hot glue to the spine of the pages. The amount of glue and the application speed can sometimes be adjusted depending on the thickness of the book and the type of binding required.

8.Align the Cover: Once the glue is applied, quickly position the cover onto the glued spine. Make sure it is aligned properly to avoid misalignment.

Press the Cover: Depending on the machine, either manually press the cover onto the spine or let the machine do it if it has an automatic cover pressing feature.

9.Allow to Cool: Let the book rest in the machine or on a flat surface to cool down. This ensures the glue sets properly and the binding is strong.

Applicable

A Hot Glue Book Binding Machine is a device that uses hot melt adhesive as a binder to bond paper, cover, and other materials together. This machine is widely used in the binding production of books, notebooks, magazines, picture albums, manuals and other publications. Here are some specific usage scenarios and material types

Book type

1.including novels, teaching materials, reference books, etc., these books are usually bound using standard paper and cover materials.

2. For books that require a higher quality appearance, such as art albums, high-end gift books, etc., the hot melt adhesive binding machine can provide a more solid and beautiful binding effect.

3.Regularly published magazines and journals are also often bound with hot glue to ensure that the content of each issue is firmly held together.

Material type

1.Various types of paper, such as coated paper, matte paper, double adhesive paper, single adhesive paper, etc., are commonly used materials for hot melt binding machines. These papers can be selected according to the needs of the book to achieve the best printing and binding results.

Cover materials: Cover materials are various, including cardboard, cloth, leather, plastic, etc. The hot melt binding machine ensures that these materials are tightly combined with the inner paper to form a beautiful and durable book cover.

2.As a key material in the binding process, the quality of hot melt adhesive directly affects the binding effect. Usually, the hot melt adhesive used for book binding has good fluidity and bond strength, which can ensure that the book is not easy to fall off during the leafing and preservation process.