High Speed Women Sanitary Pads Line Making Packing Machine Menstrual Sanitary Pad Making Machine Production of Sanitary Napkins

Model :ST-CQ1100 2 ROLLS

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Automatic Sanitary pad making machine |

|

|

Model |

OR-280 |

|

Productivity |

100~200pcs/min |

|

Napkin size |

280*155mm |

|

Power supply |

9.5KW |

|

Voltage |

220V |

|

Machine size |

4.0*1.1*1.6m |

|

Machine weight |

1000kg |

|

Automatic Sanitary pad folding machine |

|

|

Suitable pad size |

length 24-32cm |

|

Folding size |

L*W=(8-12)*9CM |

|

Folding speed |

50-100PCS/MIN |

|

Air pressure |

0.4-0.6MPa |

|

Voltage |

220v,7kw |

|

Machine size |

1700*910*1400mm |

|

Machine weight |

600kg |

|

Automatic Sanitary pad packing machine |

|

|

Bag packing size |

L*W*H=(100-200)*(90-100)*(50-100)mm |

|

Packing speed |

20-25 bags/min |

|

Machine size |

2750*750*1200mm |

|

Air pressure |

0.5MPa |

|

Voltage |

220v 2.5kw |

|

Machine weight |

300kg |

|

Condition |

New |

Product Type |

Toilet Tissue |

|

Processing Type |

Paper slitting machine |

Place of Origin |

Henan, China |

|

Weight |

1000 kg |

Warranty |

1 Year |

|

Machinery Test Report |

Provided |

Video outgoing-inspection |

Provided |

|

Marketing Type |

Hot Product 2023 |

Warranty of core components |

1 Year |

|

Core Components |

PLC, Pressure vessel, Motor, Other |

Brand Name |

Allraising |

|

Voltage |

380V |

Power |

9.5 kw |

|

Dimension(L*W*H) |

4000*1100*1600mm |

Product name |

Sanitary Pad Making Machinery |

|

Napkin size |

280*155mm |

Power supply |

9.5KW |

|

Suitable pad size |

length 24-32cm |

Speed |

150-200m/min |

|

Folding size |

L*W=(8-12)*9CM |

Folding speed |

50-100PCS/MIN |

|

Processing Type |

Lady's Pad Making Machine |

Machine for |

Production of sanitary napkins |

|

Keyword |

Sanitary pads making machine automatic |

|

|

Product Description

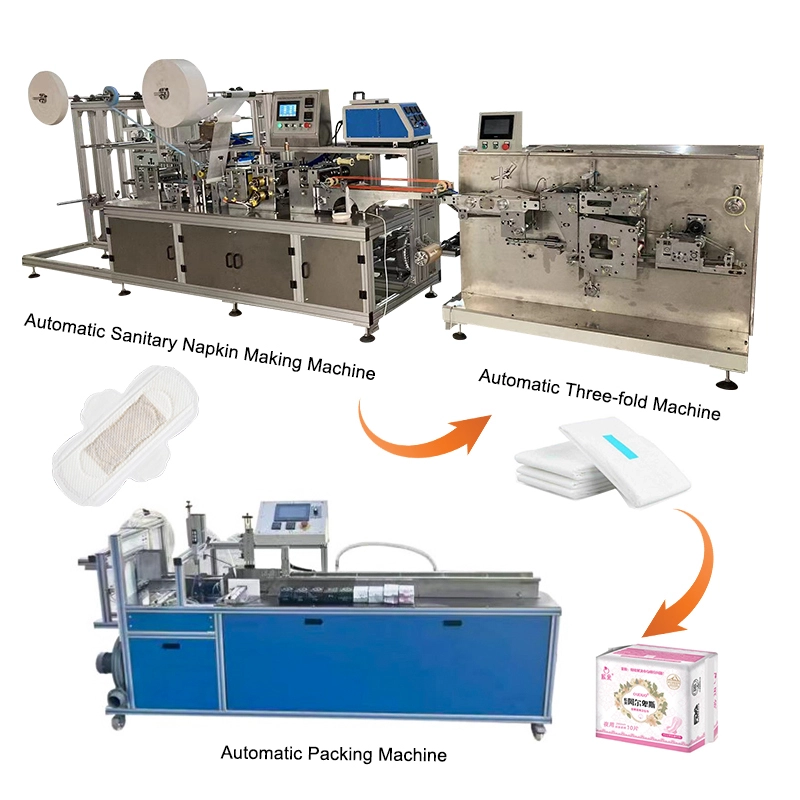

The Sanitary Napkin Making Machine is the heart of the production line, tasked with the assembly of various layers that form the sanitary napkin. This machine combines multiple materials including the absorbent core (often made of superabsorbent polymer and wood pulp), the liquid-impermeable backsheet, and the liquid-permeable topsheet. It also includes the addition of wings, if applicable, and the adhesive strip for securing the napkin in place. The machine is equipped with precision rollers and cutters to ensure uniform thickness and size of the napkins. Advanced models may feature automated systems for material feeding, quality control checks, and waste management.

Once the napkins are assembled, they are conveyed to the Sanitary Napkin Folding Machine. This machine is responsible for folding the napkins into the desired compact shape, making them easier to package and more convenient for use. The folding process is crucial for maintaining the hygiene and presentation of the product. The machine uses a series of guided folds to ensure that the napkins are neatly folded and aligned. Some machines can perform complex folding patterns, such as Z-folding, which is common for sanitary napkins to fit into individual wrappers.

After folding, the napkins proceed to the Sanitary Napkin Packaging Machine, which wraps each napkin individually in a protective cover, typically made of polyethylene film or biodegradable materials. The packaging machine can be configured to include an inner plastic wrap for each napkin, followed by a secondary outer packaging for multi-napkin packs. It seals the packages using heat sealing technology to ensure airtight closure, preserving the cleanliness and sterility of the product.

Sanitary Napkin Making Machine Key Selling Points:

•Automation and Efficiency: This machine automates the entire process of napkin creation, from layering materials to cutting and initial shaping. It significantly increases production capacity and reduces labor costs.

•Precision and Quality Control: Utilizing advanced technologies, the machine ensures that each napkin meets high standards of quality and consistency, with accurate layer alignment and cutting.

•Customization Capabilities: It can be configured to produce napkins of varying sizes, absorbencies, and designs, catering to diverse market needs.

•Hygiene and Safety: Designed with hygiene in mind, the machine minimizes human contact with the product, ensuring a clean and sterile manufacturing environment.

Sanitary Napkin Folding Machine Key Selling Points:

•Smooth and Accurate Folding: The machine folds each napkin precisely, maintaining the structural integrity and presentation quality of the product.

•Speed and Productivity: It operates at high speeds, maximizing the throughput of the production line without compromising on the quality of the folding.

•Flexibility: Can handle different napkin sizes and folding patterns, adapting to various product specifications.

•Ease of Maintenance: Typically designed for easy cleaning and maintenance, minimizing downtime and ensuring a smooth production flow.

Sanitary Napkin Packaging Machine Key Selling Points:

•Automated Packaging: Seals and packages individual napkins or groups them into multipacks, increasing efficiency and reducing the potential for contamination.

•Reliable Sealing Technology: Ensures that each package is securely sealed, protecting the product from external contaminants and preserving its hygiene until use.

•Customizable Packaging Options: Can adapt to various packaging materials and designs, offering flexibility in branding and product differentiation.

More Details

Product Show

Applicable