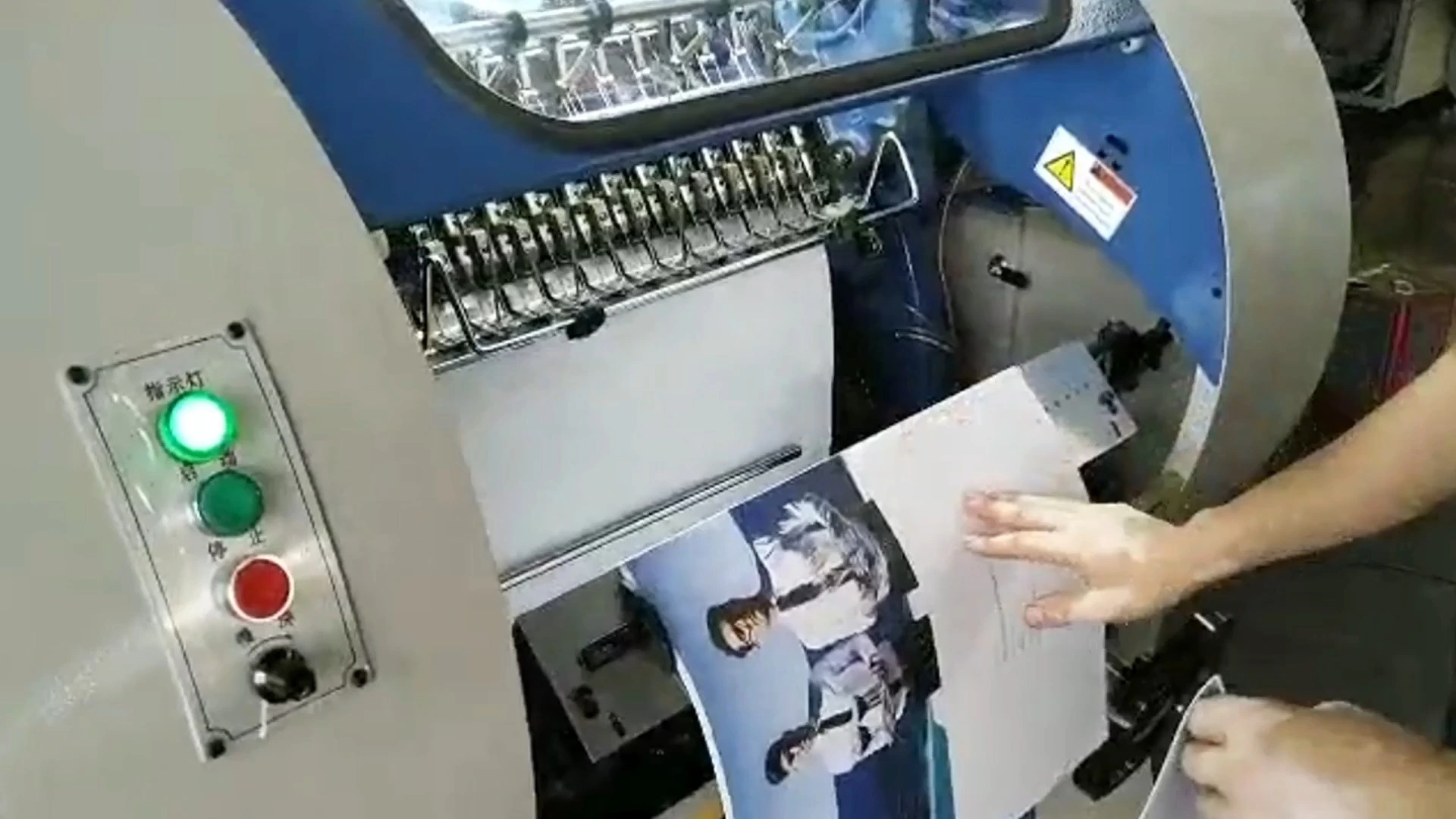

SX-460B automatic industrial paper stitching binding machine large format notebook book binding sewing machine.

Model :ZM-SX-460B

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:PRINCE

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Model |

SX-460B |

|

Max.Sewing Size |

460*460mm |

|

Min.Sewing Size |

150*100mm |

|

Sewing Speed |

About 65 Cycles/Minute |

|

Number of Needle Sets(Max) |

12 |

|

Needle Interval |

19mm |

|

Power Required |

0.55KW |

|

Overall Dimensions |

500*1300*1445mm |

|

Machine Gas |

0.6MPa |

|

Weight |

850kg |

|

Specification |

500*1300*1445mm |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

Warranty of core components |

2 years |

|

Core Components |

Hard Cover Book Machine |

Place of Origin |

Henan, China |

|

Weight |

750 KG |

Warranty |

2 years |

|

Key Selling Points |

Automatic |

Condition |

New |

|

Automatic Grade |

Automatic |

Brand Name |

Prince |

|

Voltage |

220 |

Dimension(L*W*H) |

1640*1550*1680mm |

|

Product name |

Binding Sewing Machine |

Function |

Binding Sewing Machine |

|

Max. size |

460*460mm |

Min.size |

150*100mm |

Product Description

SX-460B sewing machine special for large size of books is developed and improved according to users’ requirement.The machine adopts the features of wide sewing range,stable operation,convenient operation,low noise,and safety design etc.Thin needle and dense needle sets design make the sewing job much more perfect.Frequency conversion speed control, electromagnetic clutch driving and electromagnetic brake for main machine are adopted,Also,sensor protection is equipped on the control button panel.

more feature

1.The SX-460B sewing machine incorporates advanced frequency conversion speed regulation technology, enabling users to adjust the sewing speed with unprecedented precision and flexibility. This feature allows for seamless adaptation to different materials and sewing tasks, ensuring optimal performance and efficiency in every operation.

2.The SX-460B sewing machine is fitted with reliable electromagnetic clutch drive and braking systems, ensuring smooth and controlled starts and stops. The electromagnetic clutch efficiently transfers power from the motor to the sewing mechanism, allowing for precise control over the sewing process. The electromagnetic brake provides instant stopping power when needed, ensuring safety and preventing unintended movement of the machine.

3.To ensure the safety and reliability of the SX-460B sewing machine, the control button panel is equipped with a sensitive sensor protection system. This sensor constantly monitors the panel for any signs of overheating,tampering, or other potential issues. In the event of any irregularities, the sensor will automatically shut down the machine or trigger an alarm, preventing potential damage or accidents. This added layer of protection not only safeguards the machine itself but also ensures the safety of the operator and the surrounding environment.

Product Compare

Model: | ||

SX-460B(jumbo) | SX-460B(Large format) | |

Max.Sewing Size(mm) | 630*460(720*460) | 560*460 |

Min.Sewing Size(mm) | 150*100 | 150*100 |

Sewing Speed(cycles/minute) | About 60 | About 60 |

Number of Needle Sets(Max.) | 17 | 12 |

Needle Interval(mm) | 19 | 19 |

Power Required(KW) | 0.75(380V ordinary motor) | 1.8(220V servo motor) |

Overall Dimensions(mm) | 1500*1470*1445 | 1500*1300*1445 |

Machine Weight(KG) | About 1000 | About 850 |

Noto | Alloy swing arm | Ordinary swing arm |

Product Show

Applicable

A sewing and binding machine is a versatile piece of equipment used in the bookbinding and textile industries to stitch together materials, typically for producing books, magazines, or similar bound products. This machine combines sewing and binding functions, allowing it to efficiently stitch the pages or fabric together and secure them with a binding material, such as thread or wire.

In the context of bookbinding, the sewing and binding machine works by stitching the pages along the spine, either through saddle stitching (stapling along the fold) or side stitching (stapling or sewing along the edge), depending on the desired binding style. The machine then applies a binding layer, such as glue, cloth, or other materials, to reinforce the spine and ensure the durability of the finished product.

In the textile industry, these machines can be used to stitch and bind fabric edges, create hems, or attach various layers of material together. The sewing and binding machine is valued for its speed, precision, and ability to handle high volumes, making it essential in both large-scale production environments and specialized craft applications. These machines are often adjustable, accommodating different sizes, materials, and stitching patterns to meet specific production needs.