![1.jpg]()

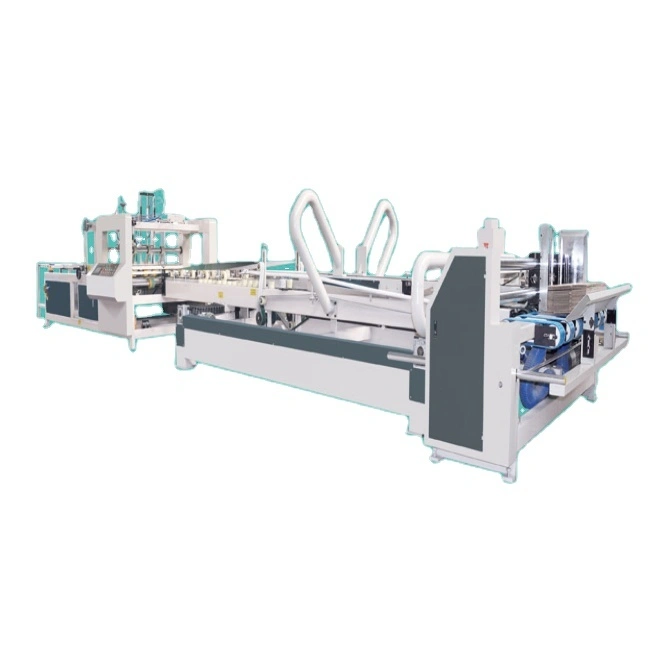

Machine introduction

QZD2600 automatic folder gluer machine consists of three parts: paper feeding part, glue folding part and correction stacking part. PLC digital display speed adjustment, remote control speed adjustment,Touch screen computer adjustment has a simple, fast and reliable control mode. Automatic paper feeding, automatic glue folding, automatic counting, automatic stacking output, front and rear synchronous double frequency conversion operation, average gluing speed of 120 m / min, maximum speed of 160 m / min, with storage order memory function. high efficiency, energy saving and environmental protection is our supreme pursuit.

Main Features

1. Automatic finish folding and gluing.

2. Suitable for wide range cartons, easy and fast adjustment of different sizes of cartons.

3. The whole machine runs smoothly and reliably, and the packaging effect is firm and beautiful.

4. Easy to operate and easy to maintain.

5. Equipped with a separate pre-pressing wheel, it effectively solves the problem of poor press line pressure of printer, automatically corrects the straight angle of the carton, and effectively corrects the phenomenon of scissors and fishtails.

6. The delivery section is equipped with a separate correction system to effectively control the carton scissors.

ProductStructure

Control instrument department:

Simple touch screen operation input, the whole machine adopts PLC computer programming controller, digital operation, touch screen input data, can realize data change and production speed without stopping, automatic feeding, automatic folding, automatic counting, automatic stacking output, gluing Box speed 120 m / min, maximum speed 160 m / min.

Feeding part:

![2.jpg]()

1. The paperboard height adjustment structure adopt high-quality steel,quickly adjust various box heights and cardboard lengths.

2. The suction belt of the paper feeding part adopt high-tech materials, and the tension layer seamlessly butts the endless belt to ensure that the machine has no worries in use.

3. The paper feeding unit suction motor and main drive motor use high quality and high stability motor from Taiwan.

4. Adopt the high-grade electromagnetic clutch and electromagnetic brake system so that the paper feeding part can be operated single or continuously, and the waste of the paperboard can be effectively controlled during the specification adjustment.

Folding and gluing part

1. The motor is imported from Taibang brand, with stable performance, convenient speed regulation and no noise pollution.

2. The folding part adopts the seamless butt-shaped endless conveyor belt made of imported high-friction and super-wear special special materials to complete the automatic folding of the cardboard without any mistakes.

3. The rubberized part adopts high quality stainless steel, which is evenly coated and energy efficient.

4. The folding section is equipped with a double-track indentation correction device to accurately and effectively correct the deviation of the cardboard pit line, so that the entire carton can be folded with the most precision.

Corrected stacking output

![3.jpg]()

The automatic calibration and stacking output unit is equipped with automatic counting, stacking tightly, and stacking output. The output of the finished box can be set according to customer requirements, and the irregularly shaped carton such as scissors is automatically forcibly corrected.

Accessory selection

1. The whole machine uses 380V AC, power 11.5KW, energy saving and high efficiency

2. PLC computer components, frequency conversion components and electrical components are all selected from high quality imported components.

3. The belt adopt imported circular seamless butt belt.

4.Bearings use internationally renowned brand LK bearings .

5.Screw screw, screw and nut are selected 45# high-quality steel, quenching processing.

Product model parameters: (total mass about 5 tons)

Model | QZD2600 |

Max.Cardboard | 2500*1800mm |

Min cardboard | 800*300mm |

Power Required | 11.5KW |

The automatic folder gluer machine is designed and produced according to the European standard, the work performance is safe and reliable, and the operation and maintenance are simple and convenient. The whole machine can be controlled by the front paper feeding part, the rear end correction part, the left end and the right end of the middle folding part, and the four directions of the remote control are adjusted and manipulated, which greatly facilitates the convenience of humanized operation. This machine selects international famous brand color touch man-machine interface and Japan Panasonic main control PLC control, touch man-machine interface and main control PLC are reserved with program upgrade interface. Convenient equipment upgrades for use.

The power of the whole machine is selected by Taibang Motor as the main power, and equipped with two world-famous brands Delta Delta frequency converters, so that the whole machine can be adjusted synchronously, the running speed is stable and reliable, energy saving and high efficiency (saving rate is about 35%) and the motor Implement full-time protection (when the voltage is too high or too low, the motor will overheat or the current is too large, the inverter will automatically alarm and stop working. There is a corresponding alarm code displayed on the display unit screen).

All electrical control contactors of the whole machine are equipped with Siemens AC contactors, and equipped with thermal overload relays, which effectively protect the smooth running of the motor. The external power supply wires of all parts of the machine are connected by aviation plugs, which makes the disassembly and maintenance more convenient. The panel uses the functions of Chinese and English and graphic reference buttons to make the operation easier and easier to understand.

Introduction to major electrical appliances

NO. | Component name | Qty | Brand |

1 | touch screen | 1 | DELTA |

2 | PLC | 1 | DELTA |

3 | Frequency converter | 2 | DELTA |

4 | Intermediate relay | 3 | Omron |

5 | Photoelectric switch | 4 | Omron |

6 | Switching power supply | 9 | DELTA |

7 | Thermal overload relay | 3 | DELTA |

8 | breaker | 2 | DELTA |

9 | Limit switch | 4 | DELTA |

10 | Contactor | 3 | Siemens |

11 | button | 11 | Schneider |