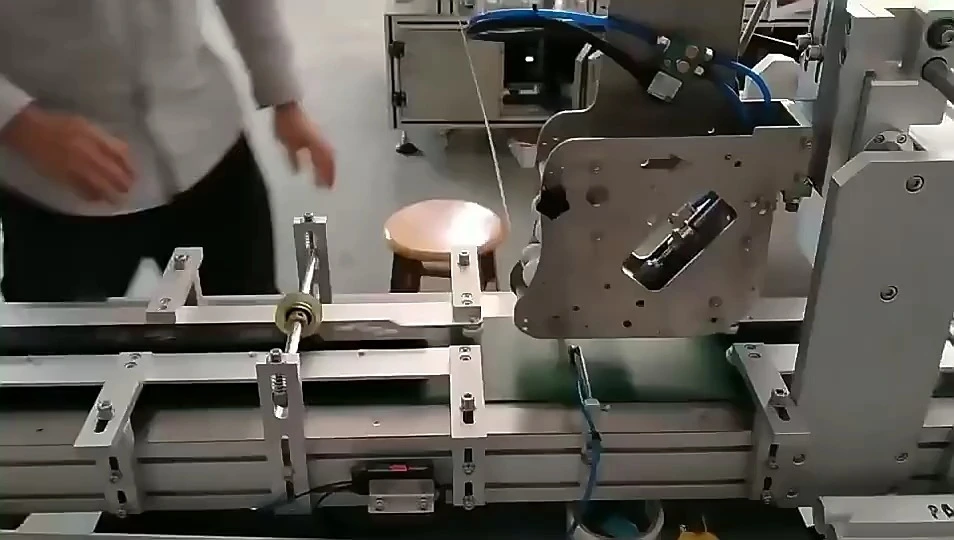

Automatic Double Sided Adhesive Tape Applicator Machine for 3M Tape Foam Diverse Materials

- High-Precision Application: Achieves ±0.1mm positioning accuracy with CCD vision system for perfect alignment on irregular shapes.

- Exceptional Efficiency: Operates at speeds up to 120pcs/min, increasing production efficiency by 500% compared to manual operation.

- Wide Material Compatibility: Handles various tape types including 3M, foam, and specialized adhesives on multiple substrates.

- Smart Cost Control: Advanced path optimization algorithm achieves 98% material utilization, saving over $15,000 annually in consumable costs.

- User-Friendly Operation: Features 7-inch touchscreen with memory storage for 100+ product parameter presets for quick changeovers.

Product Description

Automatic Customization Double-Sided Adhesive Tape Applicator Machine – Compatible with 3M Tape, Foam, and Multi-Material Tapes for Paper, Aluminum, and More.

Boost production efficiency and precision with the Automatic Customization Double-Sided Adhesive Tape Applicator Machine, engineered for applying a wide range of adhesive materials—such as 3M double-sided tapes, foam tapes, and pressure-sensitive adhesives—onto various substrates including paper, aluminum, plastic, fabric, and laminated surfaces.

This high-performance applicator delivers automated, accurate, and consistent tape placement, making it ideal for industrial manufacturing, packaging, electronics assembly, automotive trim bonding, signage, and insulation applications.

Product Features

Versatile Tape Compatibility: Supports a wide variety of tape types, including 3M VHB, foam-based tapes, acrylic, and PET double-sided adhesives.

Multi-Material Application: Efficiently applies tape to paper, aluminum sheets, composite materials, and more.

Customizable Operation: Adjustable speed, pressure, and tape width settings allow for tailored applications based on material and project needs.

Double-Sided Tape Handling: Seamlessly processes double-sided tapes with liner removal capabilities for clean and secure application.

Automatic Feeding & Cutting: Integrated tape feeding and precision cutting system streamlines the process, reducing manual labor and material waste.

Industrial Build Quality: Constructed with durable, high-grade components to withstand continuous operation in demanding environments.

Compact & User-Friendly Design: Easy setup and intuitive interface make it accessible for operators with minimal training.

Product Details

Ready to Automate Your Adhesive Application and Boost Productivity?

The DM520 Automatic Tape Applicator is more than just a machine—it's your solution for flawless bonding, reduced waste, and unmatched production efficiency.

| Product name | Double Sided Tape Applicator |

| Machine speed | 30m/min |

| Max product width | 90-500mm |

| Max material thickness | 20mm |

| Max number of spots in line | 4 |

| Min tape length | 35mm |

| Internal diameter roll tape | 76mm |

| Driven type | Electric |

| Tape applicator/taping head | 1,2,3 or 4 |

| Automatic grade | Automatic |

| PLC Language | English, Spanish,Russia |

| Application | Envelope ,A4 paper ,carton box ,PVC material |

| Video outgoing-inspection | Provided |

| Voltage | 110-220V,50HZ |

| Machinery test report | Provided |

| Dimension(l*w*h) | 950x950x1400mm |

| Weight (KG) | 150k |