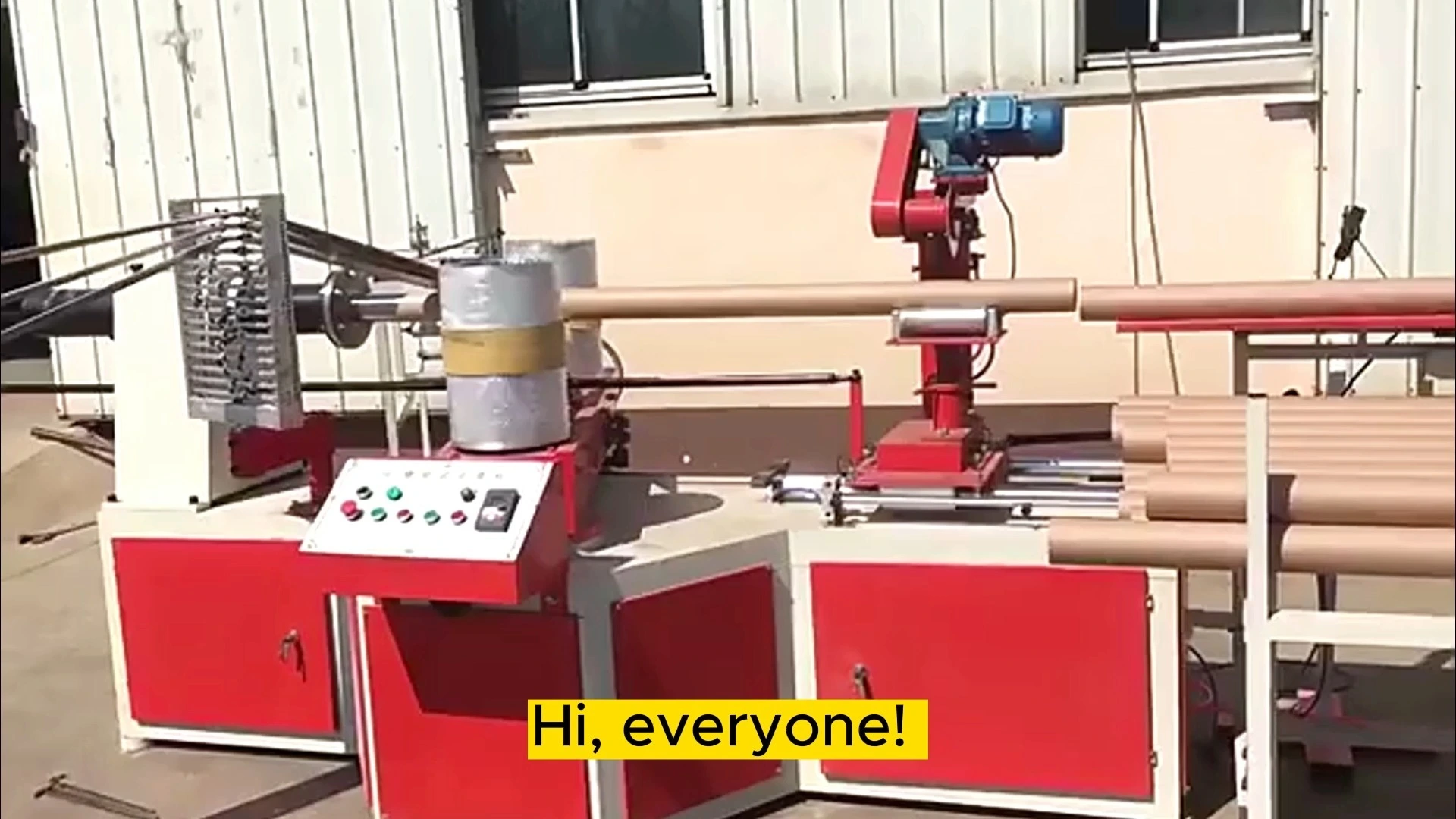

High Speed Paper Tube Making Machine Toilet Paper Core Tube Forming Cutting Machine

Model :OR-2150B

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product Specifications

Here are some product parameters that can help you quickly understand the product.

| Model | OR-2150B | OR-2150SF | OR-4250B | OR-4250SF |

| Paper layer | 3-16 layers | 3-16 layers | 3-21 layers | 3-21 layers |

| Max. pipe diameter | 150mm | 120mm | 250mm | 250mm |

| Min.pipe diameter | 20mm | 20mm | 40mm | 40mm |

| Max.pipe thickness | 8mm | 8mm | 40mm | 40mm |

| Min.pipe thickness | 1mm | 0.5mm | 1mm | 1mm |

| Speed | 3-20m/min | 3-30m/min | 3-20m/min | 3-30m/min |

| Power | 5.5KW | 7.5KW | 11KW | 15KW |

| Voltage | 380V 50Hz | 380V 50Hz | 380V 50Hz | 380V 50Hz |

| Main machine size | 2.8*1.8*1.95m | 4.2*2*1.95m | 4.2*2*1.95m | 4.2*2*1.95m |

| Weight | 1500kg | 3200kg | 4200kg | 4200kg |

| Warranty | 1year | 1year | 1year | 1year |

| Video outgoing-inspection | Provide | Provide | Provide | Provide |

Product Description

Automatic Paper Plate Making Machine

Production Process

Paper Loading: Feed kraft paper/other paper rolls into the machine; load multi-layers as per the required tube thickness and strength

Glue Application: Uniformly apply water-based adhesive to paper layers entering the forming section for secure bonding and rigidity

Tube Forming: Wind glued paper layers around a rotating mandrel into a cylinder via spiral (angled) or parallel (straight) winding

Drying: Use the machine’s built-in drying system to cure glue and solidify the paper tube quickly for better strength and shape retention

Tube Positioning: Pre-set the desired tube length manually/automatically, and the machine positions the formed tube for cutting

Cutting: Cut the tube to the specified length with circular/rotary cutters; the automatic feeding system pushes the tube forward for continuous cutting

Finished Product Collection: Collect the cut paper tubes manually/automatically into bins or onto conveyors for subsequent processing, packaging or shipment

Repeat Process: The machine cycles through the above steps to produce and cut paper tubes in batches continuously

Product Features

Product Show

Applicable

- Packaging: Winding core for films/ paper/ fabrics; protective sleeves/spacers for fragile goods

- Textile: Winding core for yarns/threads/textiles; spool/cones core in production

- Printing & Paper: Core for press/plotter/large-format printer paper rolls

- Adhesive Tape & Label: Core for tapes/labels/stickers; ensures smooth unwinding

- Construction: Concrete column casting molds; construction void forms

- Automotive & Industrial: Bushing/gasket/spacer production components

- Food: Cylindrical packaging for chips, snacks and similar products

- Craft & Stationery: Pencil holders, art materials, product display making

- Pharmaceutical & Medical: Gauze roll packaging; sterile film/bandage winding core

Related Product

Here are some other related products for you to choose from.