Plastic Bag Making Machine Supplier - - PRINCE

Product Overview

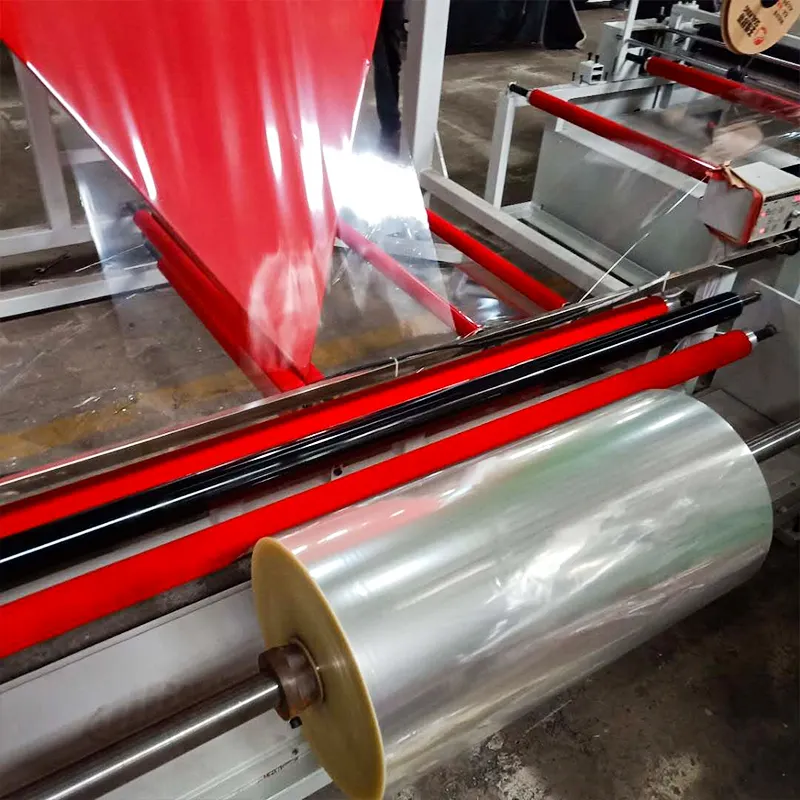

- PRINCE plastic bag making machine supplier is manufactured using high quality raw materials and advanced technology.

- The machine is part of the heat cutting machine set, suitable for folding BOPP sheet with various functions.

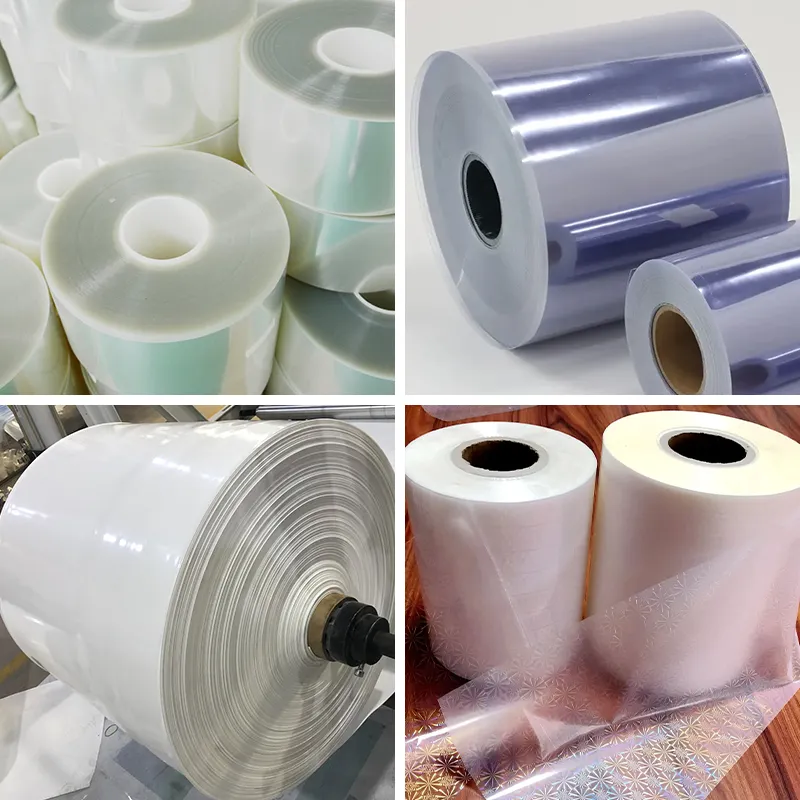

- It supports a wide range of plastic materials like polyethylene (PE), polypropylene (PP), LDPE, HDPE, and biodegradable plastics.

Product Features

- Max. speed of 150m/min and max material width of 1550mm.

- High speed production capacity.

- Automatic gluing, film laminating, hobbling, and longitudinal sealing functions.

- Programmable settings for cutting length, sealing time, temperature, and speed control.

- Machines are adjustable to produce various types of bags like flat bags, T-shirt bags, gusseted bags, and more.

Product Value

- Provides accurate cutting to minimize waste and errors.

- Adjustable cutting and sealing speed to meet different production requirements.

- Offers easy control and monitoring of parameters for enhanced machine operation.

- Suitable for a wide range of industries including retail, food, industrial packaging, garbage bags, e-commerce, agriculture, and medical.

Product Advantages

- Made from fine materials with reliable partners for quality assurance.

- Easy to operate with programmable settings for efficient production.

- Support a wide range of plastic materials for versatile use.

- High speed production capacity for increased efficiency.

- Adjustable to produce various types of bags to meet different needs.

Application Scenarios

- Retail Packaging: Making grocery bags, T-shirt bags, and flat bags for retail stores.

- Food Industry: Producing food-grade plastic bags like zip-lock pouches, produce bags, and bakery bags.

- Industrial Packaging: Manufacturing bags for storing hardware items, chemicals, and other products.

- Garbage Bags: Producing different sizes of garbage bags including flat and drawstring types.

- E-commerce, Agriculture, and Medical industries: Using the machine to create packaging for various products and purposes.