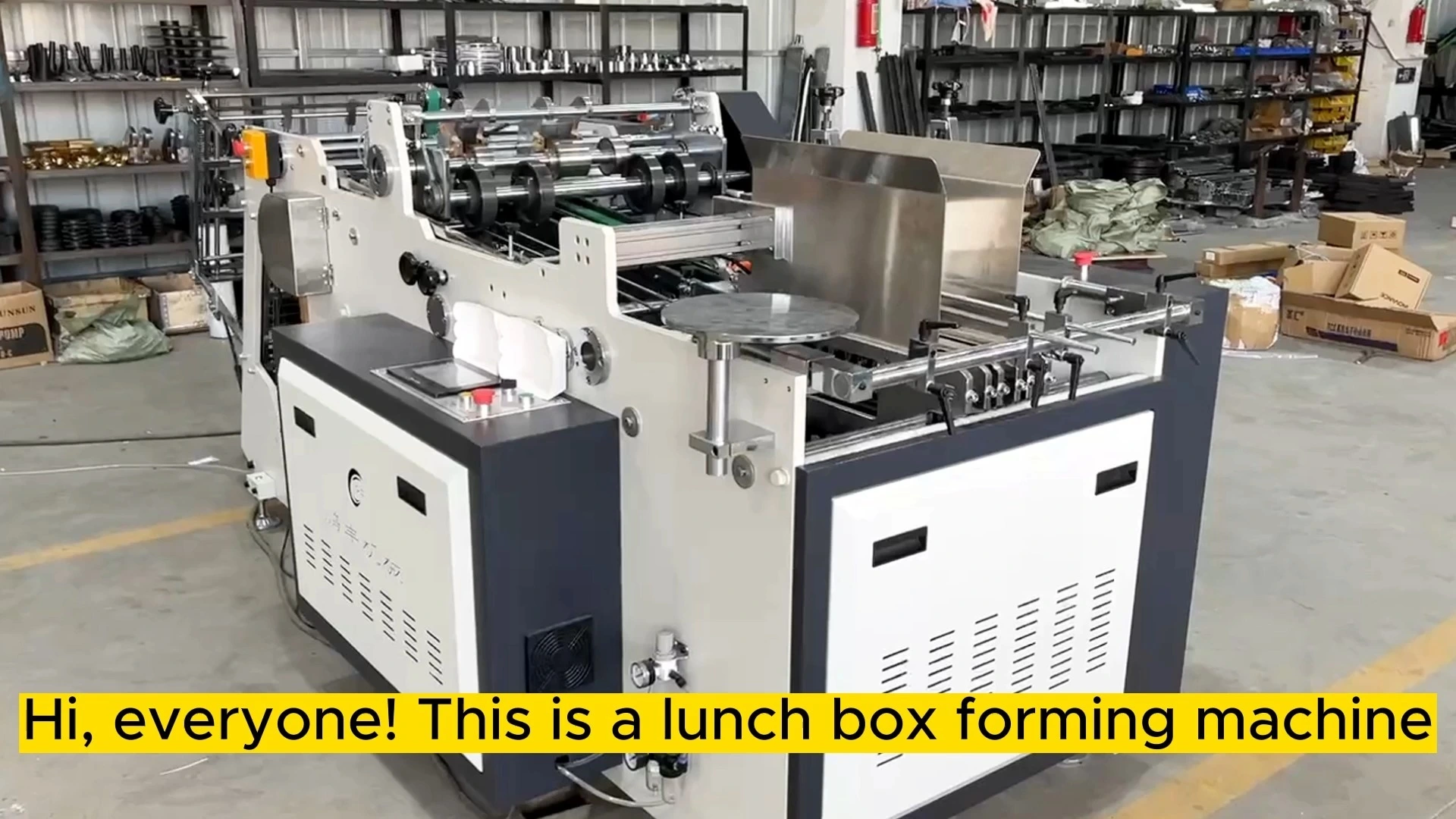

Fully Automatic Take Away Fast Food Container Paper Box Maker Machine Cake Burger Box Forming Machine Disposable Paper Lunch Box Making Machine

Model :PF-800

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Model |

Disposable Lunch Box Making Machine |

|

Paper specification |

150*150--500*380mm |

|

Raw Material |

200-600g/m2 cardboard |

|

Paper thickness |

The thickest: 1.5mm |

|

Speed range |

100-320pcs/min |

|

Width of paper feeding(Max) |

55mm |

|

Forming motor |

5.5KW |

|

Weight |

1800KG |

|

Overall size |

3300*1700*1300mm |

|

Package Size |

3350*1850*1450mm |

|

Input voltage |

Three-phase 380V/50HZ |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

Warranty of core components |

1 years |

|

Product Type |

Lunch Box Machine |

Place of Origin |

Henan, China |

|

Weight |

1800 KG |

Model Number |

PF-800 |

|

Key Selling Points |

Automatic |

Condition |

New |

|

Automatic Grade |

Automatic |

Brand Name |

PRINCE |

|

Speed specification |

150*150--500*380mm |

Video outgoing-inspection |

Provided |

|

Voltage |

380V/50HZ |

Dimensions(L*W*H) |

3300*1700*1300mm |

|

Power |

5.5KW |

Core Components |

PLC,Pressure vessel,Engine,Gear,Motor,Pump,Bearing,Grearbox |

Product Description

Hard cover book making machine is composed of a multifunctional system consisting of hot melt gluing, cover adsorption, automatic cardboard conveying, cover corner cutting, automatic edge wrapping, and quantitative water replenishment. With just one person's operation, it is possible to quickly produce high-quality, beautiful, and standardized covers for various hardcover books, photo albums, loose leaf books, diaries, desk calendars, folders, and other books. It is suitable for the production of multiple varieties, small and medium-sized book covers.

Product Feature

More Details

Product Show

Production Process

1. Material Feeding

- Raw Material Loading: The machine is loaded with raw materials such as paperboard, plastic sheets (PP, PET, PS, PVC), or biodegradable materials. For eco-friendly options, paper or plant-based materials are often used.

- Feeding Mechanism: The raw material is fed into the machine either as a sheet or a continuous roll. The feeding mechanism automatically adjusts the material and transports it into the next phase.

2. Heating or Preheating

- Heating Unit: If the raw material is plastic-based or paper with a coating, the machine will heat it to soften it and make it malleable for forming into the lunch box shape.

- Temperature Control: Precise temperature control ensures that the material is soft enough for forming without damaging it.

3. Forming or Molding

- Molding Station: The key part of the process where the material is pressed into the shape of a lunch box. The machine uses upper and lower molds to shape the box. This may involve forming a base and lid simultaneously or separately.

- Pressure or Vacuum Forming: In plastic-based machines, a vacuum is often applied to help the material conform to the mold, creating the lunch box's shape with defined edges and compartments.

- Multi-Cavity Molds: Modern machines may use multi-cavity molds, allowing multiple lunch boxes to be produced in one cycle.

4. Cutting and Trimming

- Trimming Mechanism: After the lunch box is formed, the excess material is cut away. This step ensures that the lunch box edges are smooth and uniform.

- Perforating for Folding (Paper-Based): In paper-based lunch boxes, perforations are added to allow for easy folding and assembling of the box's structure.

- Punching and Shaping: For certain designs, additional punching is done to create vents, fold lines, or other specific features.

5. Ejection

- Finished Product Removal: Once formed and trimmed, the lunch boxes are ejected from the molds. The machine usually uses a mechanical ejector or air-blowing system to release the product.

- Stacking System: Many machines have automatic stacking mechanisms to neatly arrange the finished lunch boxes for easy collection and packaging.

6. Folding and Assembly (Paper Lunch Boxes)

- Automatic Folding: For paper-based lunch boxes, the machine may have an automatic folding unit that pre-folds the creases and seals the edges, often using adhesives or heat for binding.

- Locking or Sealing: If the lunch box design requires locking mechanisms or adhesive seals, this step ensures the box is ready for packaging and use.

7. Control System

- PLC or Automated Control System: Most machines have a Programmable Logic Controller (PLC) to automate operations, control speed, regulate heat, and adjust the production parameters for different box sizes and shapes.

- Sensors and Alarms: Sensors detect malfunctions, ensuring consistent production quality. If there's an error or material misalignment, alarms alert the operator.

8. Cooling (Plastic Lunch Boxes)

- Cooling Station: If the material is plastic, the formed lunch boxes often need a cooling step to ensure they retain their shape. This may be done via air cooling or water cooling systems within the machine.

9. Finished Product Handling

- Quality Check: The lunch boxes are checked for defects such as improper sealing, shape deformation, or cuts.

- Packaging: The finished and stacked boxes are ready for packaging, which may be done manually or through an automated packing line.

Applicable

Key Features:

- Customizable Molds: Molds can be switched to create lunch boxes of various sizes, shapes, and compartments.

- High Efficiency: Modern machines are highly automated and capable of producing large quantities of lunch boxes per hour.

- Material Flexibility: Machines can handle a wide variety of materials, from plastic to paper and biodegradable options.

This process enables the production of disposable or reusable lunch boxes used in food service, takeaways, and meal packaging industries.