BL-X108 Automatic Pet Film Surface Roll to Roll Inkjet Ink Digital Label Printing Machine sticker

Model :P-BL-X108

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Color: |

CMYK+White (Varnish,Spot Color is optional) |

|

Print head: |

Kyocera,max. Printing width of one print head: 108mm |

|

Ink Tank Volume: |

3L per color |

|

Connectivity: |

Fast Ethernet |

|

Software and User Interface: |

Lable Print control software PrintFactory Rip software |

|

Main Dimensions (W x D x H): |

2010mm x 1240mm x 1850mm(79.2" x 48.8" x 72.8") |

|

Unwinder/Rewinder: |

Roll-fed Width: Max.230mm (9.1") |

|

Other device are optional: |

Rectification,Corona treatment,Web Cleaner,Antistatic treatment |

|

Pre-Curing: |

UV-LED(Air cooling) |

|

Final Curing: |

UV-LED(Water cooling) |

|

Media Width: |

Max. 230mm (9.1") |

|

Media Type: |

Coated and uncoated paper,self-adhesive label stock,aluminum foil,white and transparent films,PP,PE,PVC,PET,BOPP,etc. |

|

Media Thickness: |

0.08-0.5mm(0.003-0.02") |

|

Working Environment |

Temperature: 15-30°C(59-86F)Relative Humidity:40-60%(Recommended) |

|

Machine Weight: |

1430(Kg) |

|

Power Supply: |

Two-phase 220V(50/60HZ.AC)60A |

|

Power |

Printer: Max.4500W Corona Treatment: Max.2000W Water Cooler:1500W |

|

Air |

6-8bar,Clean and dry |

|

Auxiliary Devices |

Air-pressure utilities such as compressor; Connection to exhaust duct |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Marketing Type |

Ordinary Product |

Warranty of core components |

2 years |

|

Core Components |

Hard Cover Book Machine |

Place of Origin |

Henan, China |

|

Weight |

750 KG |

Warranty |

2 years |

|

Key Selling Points |

Automatic |

Condition |

New |

|

Automatic Grade |

Automatic |

Brand Name |

PRINCE |

|

Model NO. |

BL-X108 |

Automatic Grade |

Autpomatic |

|

Printing Interface |

Fast Ethernet |

Printing Speed |

50m/Min |

|

System Supported |

Windows xp32 |

Print Width |

108mm(4.25'')/216(8.5'') |

|

Ink |

LED-UV Curable Ink |

Print Resolution |

600*600dpi/600*1200dpi |

|

Print Speed |

up to 50m/Min(164FT/Min) |

Number of Print Heads |

4-6Heads with 108mm Configuration 8-12 Heads with |

|

Power Supply |

220V |

Usage |

Hard Cover Book Machine |

Product Description

This Label Printing Machine sticker not only excels in producing crisp and vibrant labels for product packaging, but it also allows for intricate designs and patterns to be replicated with impeccable precision, catering to the customers' aesthetic requirements. Its advanced LED production engine not only guarantees energy efficiency and environmental friendliness but also facilitates rapid printing speeds, enabling businesses to meet tight deadlines and scale up production efficiently. Widespread adoption across advertising agencies underscores its proficiency in creating eye-catching promotional materials, while in the packaging and printing industries, it has revolutionized the way products are presented to consumers, enhancing brand image and shelf appeal.

more feature

More Details

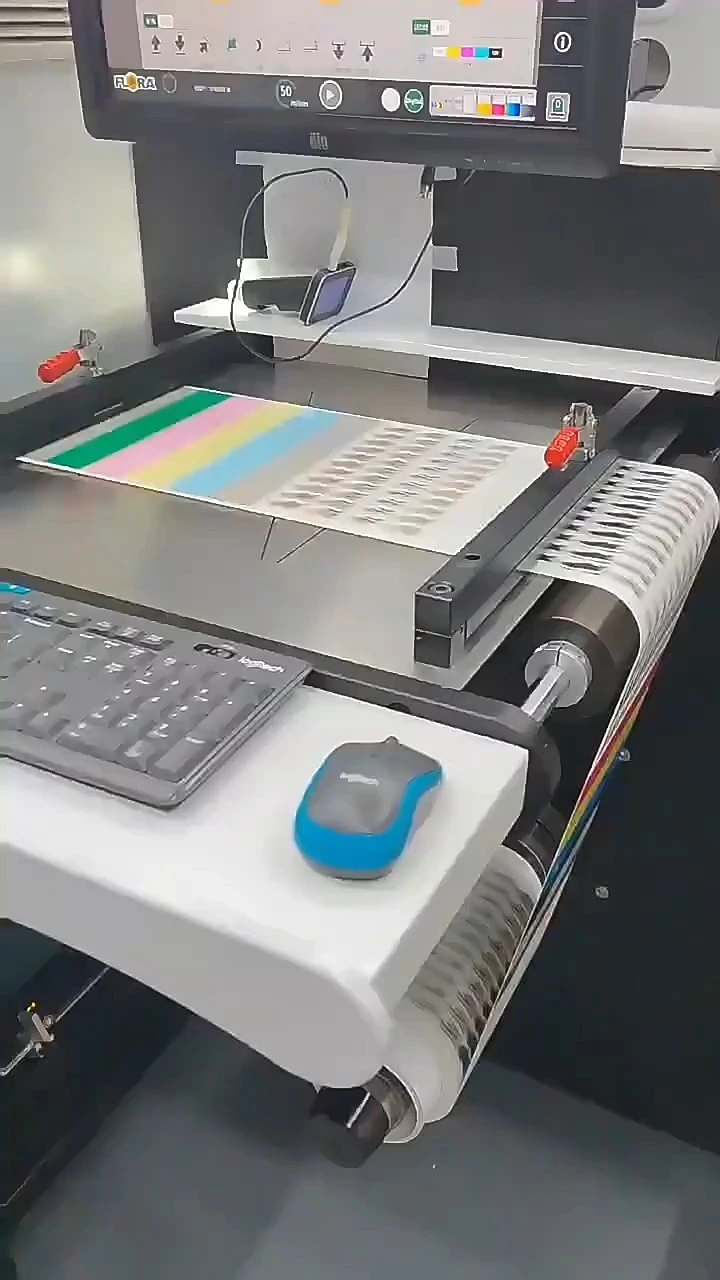

Product Show

Production Process

1. Printhead

The printhead is the most critical component of the machine. It is responsible for ejecting the ink droplets onto the substrate (the material being printed on). The printhead moves back and forth across the material, or the material moves under the printhead, allowing for precise placement of ink.

Printheads in inkjet machines can vary, with common technologies being thermal, piezoelectric, or continuous inkjet.

2. Ink Supply System

This system stores and delivers ink to the printhead. It includes ink cartridges, reservoirs, or bottles, and may have tubing or channels that feed ink to the printhead. The system ensures that the printhead receives a continuous and steady supply of ink during the printing process.

The ink supply system may also include filters to remove impurities and sensors to monitor ink levels.

3. Substrate Transport System

This system moves the substrate (e.g., label material) through the printer, ensuring it is positioned correctly for printing. It is crucial for maintaining print accuracy and consistency.

The transport system often includes rollers, belts, and sometimes a vacuum table to keep the substrate flat and in place during printing.

4. Drying/Curing System

After the ink is deposited on the substrate, it needs to dry or cure quickly to avoid smudging and to ensure durability. The drying system can use heat, UV light, or air to accelerate the drying process, depending on the type of ink being used.

UV-curable inks require UV lamps, while solvent-based or water-based inks may require heated drying systems.

5. Control Panel/Software Interface

The control panel or software interface allows the operator to manage the printing process. It includes options for adjusting settings such as print speed, resolution, ink density, and substrate type.

Modern machines often integrate with computers or networks, enabling the import of digital designs and control of multiple printers remotely.

It also optimizes the image for the specific printhead and ink type being used, ensuring the best print quality.

6. Mechanical Frame and Housing

The mechanical frame and housing provide the structural integrity of the machine. It holds all the components together and ensures that they remain aligned and stable during operation.

The frame also helps reduce vibrations and maintain precision in the printing process.

Applicable

1. High Resolution Printing

The ability to print at high resolutions (typically 600-2400 dpi) ensures sharp, clear images and text. This feature is crucial for producing labels with fine details, barcodes, and small text.

2. Wide Color Gamut

A broad color gamut allows the printer to produce vibrant, accurate colors. Some machines use CMYK inks, while others may include additional inks like white, metallic, or spot colors to enhance the range of printable colors.

3. Variable Data Printing (VDP)

Supports the printing of labels with unique, variable content on each label, such as serial numbers, barcodes, or personalized information. This feature is essential for industries requiring individualized labels, like promotional products or pharmaceutical packaging.

4. Fast Print Speeds

The ability to print at high speeds (measured in inches per second or labels per minute) without compromising quality. This feature is vital for high-volume production environments.

5. Support for Various Substrates

Compatibility with a wide range of materials such as paper, vinyl, polyester, and other synthetic materials. This versatility allows the printer to handle different types of labels, from simple paper labels to durable, weather-resistant labels.

6. Automatic Calibration

Automatic alignment and calibration features that adjust the printhead, ink flow, and substrate positioning for optimal print quality. This reduces the need for manual intervention and ensures consistent results.

7. Integrated Cutting System

Some machines include a built-in cutting system (e.g., rotary or laser cutters) that automatically trims labels to the desired size and shape after printing. This is especially useful for creating custom-shaped labels.

.