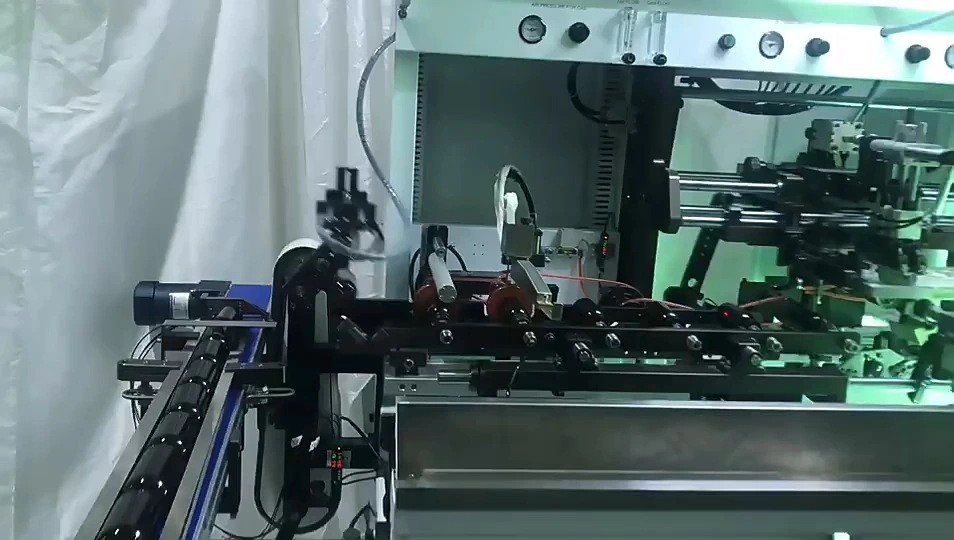

Factory Price Glass Automatic Silk Screen Printing Machine Bottle Screen Printing Machine

Model :OR-AL100

MOQ :1

Delivery time:30-60 days

Start Port :Guangzhou,Ningbo,Shenzhen ect,.

Certification :CE,IOS,RUSH ect,.

Brand:Prince

Factory Price:Negotiate

Supply Ability:1000 Set/Sets per Month

Payment Terms:L/C, Cash,T/T,Western Union ,Trade Assurance, Paypal

ODM & OEM:Available

Product parameters

|

Product Model |

ORAL100 |

|

Circular printing diameter |

ф15mm~ф100mm |

|

Circular printing height |

20mm~270mm |

|

Elliptical printing diameter |

R20mm~R180mm |

|

Elliptical printing height |

20mm~270mm |

|

Maximum printing speed |

50-60 pcs/min |

|

Power Requirements |

AC220V 1Phase/AC380V 3Phase 50Hz /60Hz |

|

Power |

main energy 7.5kw |

|

Pressure |

5-8bar |

|

Overall Dimension(LxWxH) |

1100*650*1500 |

|

Machine Weight |

950 Kg |

|

Video outgoing-nspection |

Provided |

Machinery Test Report |

Provided |

|

Application |

Packaging Printing |

Warranty of core components |

1 years |

|

Circular Printing Diameter |

R20mm-R180mm |

Place of Origin |

Henan, China |

|

Weight |

1500 KG |

Warranty |

2 years |

|

Transport Package |

Wooden Case |

Printing Colors |

1 Colors |

|

Automatic Grade |

Automatic |

Brand Name |

PRINCE |

|

Voltage |

220v |

Dimension(L*W*H) |

L2700*W2000*H1700mm |

|

Product name |

Hard Cover Book Machine |

Air Pressure |

5-8bar |

|

Max. size |

840*440mm |

Production Capacity |

500PCS/Year |

Product Description

This machine can meet the circular surface printing requirements of cylindrical, elliptic cylindrical, and other special-shaped containers, and is compatible with plastic, glass, metal,l, and other materials. This machine through the programmable logic controller (PLC) and high-performance Touch Screen (Touch Screen) achieves intelligent control of the whole machine’s work. With ADVANCED imported motors, variable speed devices, and mechanical transmission to form a new high-speed transmission system, to achieve infinitely variable speed, synchronous transmission, automatic alignment, no bottle no printing, and other control functions.

more feature

Product Show

Production Process

1. Screen Preparation

Screen Selection: A mesh screen is chosen based on the detail required for the print. Higher mesh counts are used for more detailed prints, while lower counts are used for simpler designs or thicker inks.

Coating with Emulsion: The screen is coated with a photosensitive emulsion. This emulsion will harden when exposed to UV light.

Drying: The coated screen is dried in a dark environment to prevent the emulsion from hardening prematurely.

2. Image Transfer

Exposure: The prepared design (printed on a transparent film) is placed on the screen. The screen is then exposed to UV light. The areas not covered by the design (where the ink should pass) are hardened by the light, creating a stencil.

Washing Out the Screen: After exposure, the screen is washed with water. The areas not exposed to light (the design areas) wash away, leaving open mesh that will allow ink to pass through.

3. Machine Setup

Frame Setup: The prepared screen is mounted on the screen printing machine's frame. The machine can be manual, semi-automatic, or fully automatic, depending on the scale of production.

Registration: In multi-color printing, the screens need to be aligned perfectly (registration) to ensure that each color prints in the correct position. Registration marks or guides help align the screens accurately.

4. Printing Process

Substrate Placement: The substrate (such as fabric, paper, or plastic) is placed on the printing platen or surface where the screen will transfer the ink.

Ink Application: Ink is applied to the top of the screen. A squeegee is then used to push the ink through the open mesh areas of the screen and onto the substrate.

Screen Lifting: After the ink is transferred, the screen is lifted, and the printed substrate is removed.

5. Drying and Curing

Drying: The printed item is moved to a drying or curing unit, which helps to dry or cure the ink. Plastisol ink, commonly used in textile printing, needs heat curing, while water-based inks may dry naturally or be dried with air.

Flash Curing: In multi-color printing, sometimes a flash curing unit is used between colors to partially dry the ink before printing the next color.

Applicable

1. Textile Printing

T-shirts and Apparel: Screen printing is one of the most common methods used for printing designs on t-shirts, hoodies, and other garments. It provides long-lasting and durable prints, especially with thick inks like plastisol.

Uniforms and Sports Apparel: Companies and sports teams use screen printing to create logos, numbers, and branding on uniforms and jerseys.

2. Advertising and Promotional Products

Banners and Posters: Large format screen printing is often used for producing banners, posters, and outdoor advertising materials.

Promotional Items: Screen printing is used to create custom designs on items like tote bags, caps, mugs, and other promotional products.

3. Packaging and Labels

Product Packaging: Many consumer products use screen printing for packaging design, especially for custom designs on boxes, bottles, and containers.

Labels and Stickers: Durable labels and decals for branding, safety signs, and industrial applications are commonly printed using screen printing techniques due to their high quality and durability.